ENiFe-Cl Mig Welding Wire

| Specifications of ENiFe-Cl Mig Welding Wire: |

ENiFe-CI MIG welding wire, specially designed for welding and repairing gray cast iron, ductile iron, and cast iron components joined to steel. This nickel-iron alloy filler wire conforms to AWS A5.15 ENiFe-CI, offering excellent strength, ductility, and machinability.With superior resistance to cracking and thermal fatigue, it is ideal for repairing engine blocks, pump housings, gearboxes, and other castings exposed to dynamic loads or thermal cycling. The weld deposits are fully machinable, making post-weld processing easy and efficient.

| Grade | ERNiCrFe-7,ERNiCrFe-7A,ERNiFeCr-1,ERNiFeCr-2,ERNiCrFe-11 |

| Standard | AWS A5.14 |

| Length | 100 mm TO 6000 mm, customizable |

| Diameter | 10 mm To 100 mm or as per client requirement |

| Types | Filler Wire, Coil Wire, Electrode Wire, Welding Wire, Wire mesh, Knitted wire mesh, filter mesh, mig wire, tig wire, spring wire |

| Surface | Polished bright, Smooth |

| Technology | Cold Rolled, hot rolled |

| CHEMICAL COMPOSITION OF ENiFe-CI welding wire: |

| Grade | Fe | Ni | Cu | S | C | Mn | Si |

| ENiFe-CI | Rem | 45.0-60.0 | 2.5 | 4.0 | 2.0 | 2.5 | 4.0 |

| ENiFe-CI wire Mechanical Properties: |

| Tensile Strength | Yield Strength | Elongation |

| 84,000 psi | 59500 psi | 9% |

| ENiFe-CI welding wire Features: |

1.Excellent crack resistance – ideal for welding cast iron with minimal risk of hot cracking

2.Machinable weld deposits – easy to cut, drill, or machine after welding

3.Strong and ductile joints – suitable for dynamic and thermal stress environments

4.Versatile compatibility – can join cast iron to cast iron or even cast iron to steel

5.Stable arc performance – ensures smooth metal transfer and easy operation with MIG process

6.Low porosity – clean, high-integrity welds with proper shielding gas

| ERNICRFE-12 welding wire applications: |

1.Gray Cast Iron Repair: Used for repairing cracks and damage in engine blocks, cylinder heads, gearboxes, and pump housings.

2.Ductile Iron Welding: Suitable for welding ductile (nodular) iron castings exposed to mechanical vibration or thermal cycling.

3.Dissimilar Metal Joining: Effective for joining cast iron to carbon steel or stainless steel components.

4.Industrial Equipment Maintenance: Applied in foundries, mining, power plants, and heavy machinery repair.

5.Automotive and Locomotive Restoration: Commonly used in reconditioning engine and transmission components.

6.Machinable Welds for Precision Applications: Ideal where post-weld machining such as drilling or tapping is required.

| SASA ALLOY'S Quality Assurance: |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| Why Choose Us: |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. Provide SGS TUV report.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

7.Provide one-stop service.

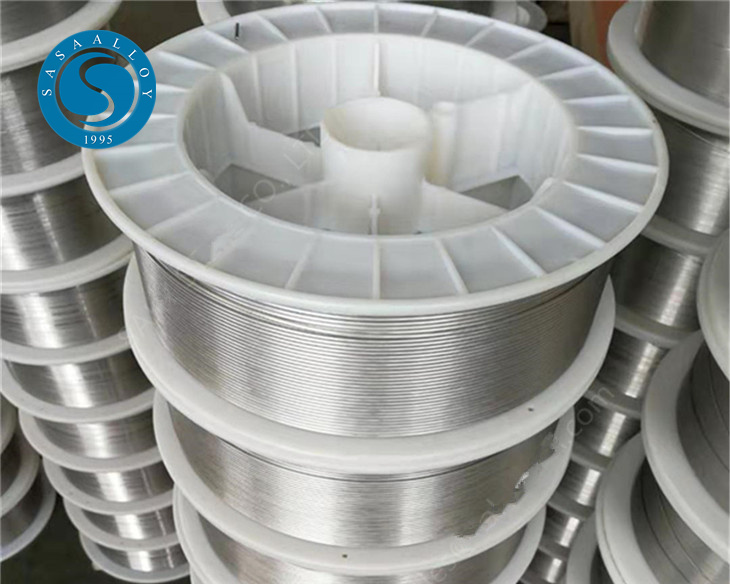

| MIG wire Packing: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa alloy’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,