An Inconel 625 Bar owes its survival capabilities to a unique alloy composition. This specific blend of nickel, chromium, molybdenum, and niobium delivers exceptional performance. It provides superior resistance to high temperatures and corrosive media, far exceeding materials like the Inconel 600 round bar. The growing demand for such high-performance alloys is clear.

| Metric | Value |

|---|---|

| Market Size (2024) | USD 120 million |

| Forecast (2033) | USD 214.02 million |

| CAGR | 7.5% |

This makes the Inconel 625 Bar the premier material for critical applications where endurance is the primary requirement.

Key Takeaways

- Inconel 625 is a special metal that can survive in very tough places.

- It has nickel, chromium, and other elements that make it strong against heat and rust.

- This metal is used in jet engines, under the sea, and in power plants because it is so tough.

- Inconel 625 is better than regular steel for extreme jobs.

- Even though it costs more at first, it saves money over time because it lasts so long.

The Anatomy of Resilience: Deconstructing the Alloy

The remarkable survival instincts of an Inconel 625 bar are not accidental. They are engineered at the atomic level through a precise and synergistic combination of elements. Each component in this superalloy plays a distinct, critical role, working together to create a material that thrives where others fail. The foundation of this resilience lies in its specific chemical makeup.

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 58 min |

| Chromium (Cr) | 20 – 23 |

| Molybdenum (Mo) | 8 – 10 |

| Niobium + Tantalum (Nb + Ta) | 3.15 – 4.15 |

This powerful recipe creates a unified defense system, with each element contributing a unique strength to the alloy’s overall performance.

The Nickel-Chromium Shield Against Heat

The alloy’s primary defense against high-temperature oxidation and corrosion comes from its nickel-chromium matrix. The high nickel content provides a stable base that resists degradation, while chromium acts as the frontline guardian. When exposed to extreme heat, the chromium reacts with oxygen to form a durable, tightly-adherent, and passive oxide layer (Cr₂O₃). This microscopic shield effectively seals the underlying material from further attack.

The process is enhanced by other elements. Molybdenum promotes chromium diffusion to the surface, accelerating the formation of this protective layer. Niobium also contributes by forming NbCrO₄ alongside the chromia, further reinforcing the shield.

Inconel 625 maintains its exceptional strength and creep resistance in continuous service at temperatures up to approximately 1,800°F (982°C). It demonstrates outstanding oxidation resistance at both 800°C and 1000°C, proving its reliability in punishing thermal environments.

Molybdenum’s Defense Against Corrosion

Molybdenum is the key element that gives Inconel 625 its formidable resistance to a wide range of corrosive media, particularly in acidic and chloride-rich environments. It provides a multi-faceted defense against localized attacks like pitting and crevice corrosion. Molybdenum’s defensive actions include:

- Impeding the penetration of aggressive ions, such as chloride (

Cl⁻), into the protective oxide film. - Reducing the rate of active dissolution if the passive film is ever compromised.

- Promoting the rapid self-repair of the protective oxide film.

- Suppressing the dissolution of the passive film itself.

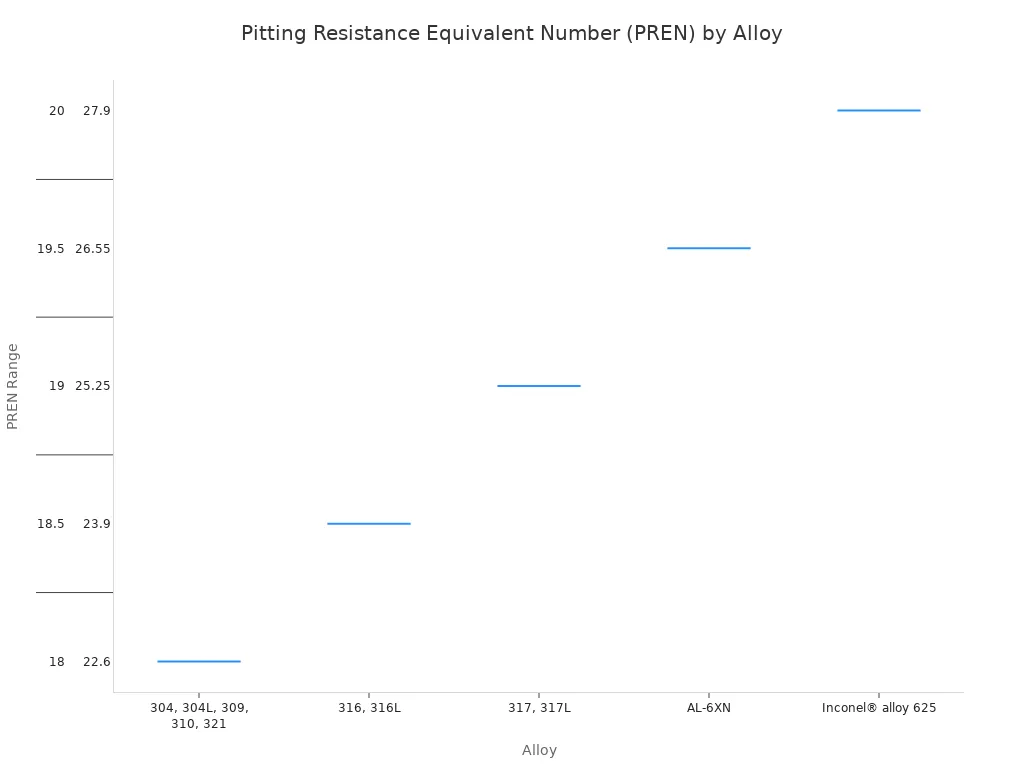

This robust defense is quantified by the Pitting Resistance Equivalent Number (PREN), a measure of an alloy’s resistance to pitting corrosion. A higher PREN indicates superior resistance. Inconel 625 boasts a PREN that far surpasses many standard stainless steels, making it a reliable choice for seawater and chemical processing applications.

| Alloy | PREN Range |

|---|---|

| 316, 316L Stainless Steel | 22.6 – 27.9 |

| 317, 317L Stainless Steel | 27.9 – 33.2 |

| Inconel® alloy 625 | 46.4 – 56.0 |

| Hastelloy® alloy C-276 | 64.0 – 73.8 |

Note: A PREN of 32 is the accepted minimum for reliable seawater pitting resistance.

Niobium’s Role in Fortifying Strength

While other elements provide the shield, niobium delivers the muscle. It works in concert with molybdenum to stiffen the alloy’s matrix, providing immense strength without requiring a separate strengthening heat treatment. This solid-solution strengthening is a baseline feature of the alloy.

However, its most significant contribution comes from a process called precipitation hardening. When the alloy is heated within a specific range (1200-1600°F or 649-871°C), niobium precipitates to form extremely fine particles of a phase known as gamma double prime (γ″), or Ni₃Nb. These microscopic particles act like internal anchors within the metal’s grain structure. They effectively lock the structure in place, preventing slip and deformation under immense stress. This mechanism dramatically increases the alloy’s tensile and yield strengths, giving it the fortitude to withstand extreme pressure and mechanical fatigue.

An Inconel 625 Bar in the Face of Extremes

The true test of a material’s survival capability lies in its performance under real-world, punishing conditions. An Inconel 625 bar does not just endure extreme environments; it dominates them. Its engineered alloy composition translates directly into tangible resilience against thermal shock, chemical attack, and immense physical stress. This section explores how the material confronts and overcomes these challenges, proving its mettle time and again.

Dominating High and Low Temperatures

Inconel 625 exhibits remarkable thermal stability across an exceptionally wide temperature spectrum. At elevated temperatures, where many metals weaken and fail, it maintains its structural integrity and strength. This is due to the solid-solution strengthening effect of molybdenum and niobium, which stiffens the nickel-chromium matrix. The alloy resists creep and rupture under load at continuous service temperatures up to 1,800°F (982°C).

Its performance extends to cryogenic temperatures as well. Unlike many ferrous materials that become brittle and fracture in extreme cold, Inconel 625 retains its ductility and toughness. This dual-threat capability makes it an invaluable material for applications that experience severe thermal cycling, from the fiery heat of jet engine exhausts to the frigid cold of liquefied natural gas (LNG) systems.

Did You Know?

The unique atomic structure of Inconel 625 prevents the formation of brittle phases at low temperatures, ensuring it remains tough and resistant to impact fractures even in cryogenic conditions.

Conquering the Corrosion Gauntlet

Inconel 625 provides a formidable defense against a vast array of corrosive agents. Its high nickel and chromium content creates a stable, passive oxide layer that protects it from general corrosion. The significant addition of molybdenum provides exceptional resistance to localized attacks like pitting and crevice corrosion, which are particularly damaging in chloride-rich environments such as seawater.

The alloy’s versatility is one of its greatest strengths. It demonstrates outstanding resistance to various acids, including phosphoric, nitric, and sulfuric acid. This allows for safe, long-term operation in aggressive chemical process streams at both ambient and elevated temperatures. A case study on additively manufactured Alloy 625 confirmed its inherent immunity to chloride stress corrosion cracking, a failure mode that plagues many lesser alloys. This resistance was found to be equivalent to that of traditionally manufactured Inconel, highlighting the material’s fundamental resilience.

The data below quantifies its superior performance in several aggressive environments.

| Environment | Concentration | Temperature | Corrosion Rate (mm/year) |

|---|---|---|---|

| Sulfuric Acid | 5% | 60°C | <0.05 |

| Seawater | 35,000 ppm Cl⁻ | Ambient | <0.01 |

This exceptional corrosion resistance ensures reliability and longevity in marine, chemical processing, and petrochemical applications where material degradation could lead to catastrophic failure.

Withstanding Intense Pressure and Fatigue

Mechanical strength is the final piece of Inconel 625′s survival puzzle. The alloy’s unique microstructure, fortified by niobium and molybdenum, gives it immense tensile, creep, and rupture strength. It can withstand enormous pressures and mechanical loads without deforming or failing, making it ideal for high-pressure vessels, downhole drilling equipment, and subsea hardware.

Furthermore, the alloy possesses excellent fatigue resistance, ensuring its durability in environments with repeated mechanical loads. This is critical in applications like jet engines and power generation turbines, which are subject to constant vibration and cyclic stress.

- Inconel retains its fatigue resistance at elevated temperatures, a condition where many other alloys, including titanium, would experience a significant loss in performance.

- While some materials offer good fatigue properties in specific conditions, Inconel’s combination of high-temperature strength, creep resistance, and fatigue endurance makes it the superior choice for long-term, high-stress cyclic applications.

Its high fatigue limit means it can endure more stress cycles before failure, providing a greater margin of safety and reliability in the most demanding mechanical systems.

Proven Performance: Where Inconel 625 Bar Thrives

The theoretical strengths of Inconel 625 translate into dominant, real-world performance. Industries facing the most hostile conditions rely on this superalloy for safety and operational continuity. Its unique combination of heat resistance, corrosion immunity, and mechanical strength makes it the material of choice where failure is not an option.

Aerospace and Jet Propulsion Systems

The aerospace industry demands materials that perform under extreme thermal and mechanical stress. Inconel 625 meets these demands, especially within the punishing environment of jet engines. It retains its strength at the high temperatures found in propulsion systems, ensuring structural integrity. Key applications include:

- Engine exhaust and thrust-reverser systems

- Turbine shroud rings and seals

- Compressor vanes and bellows

- Combustion chambers and tailpipes

Its resistance to oxidation and thermal fatigue ensures long service life and reliability for these critical flight components.

Marine and Subsea Engineering

Marine environments present a relentless corrosion challenge, particularly from chloride-rich seawater. An Inconel 625 Bar provides exceptional resistance to pitting, crevice corrosion, and stress-corrosion cracking. This makes it indispensable for long-term subsea and naval applications.

The alloy’s durability ensures the reliability of vital equipment, from submarine fittings and propeller blades to the mooring lines that secure massive vessels. It is also a preferred material for subsea electrical cable connectors and sensitive oceanographic instruments that must survive deep-sea pressures and corrosive water.

Chemical and Petrochemical Processing

The chemical processing industry handles highly aggressive and corrosive media. Inconel 625 provides a safe and durable barrier in these environments. It shows outstanding resistance to a wide range of acids, including sulfuric and hydrochloric acid. This allows for its use in constructing critical infrastructure like reaction vessels, heat exchangers, and complex piping systems. Its ability to withstand both corrosive chemicals and high temperatures simultaneously makes it a superior choice for reactor internals and storage tanks, protecting against leaks and ensuring process safety.

Nuclear Power and Energy Generation

The nuclear power industry operates under the most stringent safety standards, where material integrity is paramount. Inconel 625 provides the reliability required for these high-consequence environments. The alloy is a critical material for components inside nuclear water reactors, including the reactor core and control-rod systems. Its comprehensive performance profile prevents system failure and ensures safe, continuous operation.

The selection of Inconel 625 for these applications stems from a specific set of survival traits. Its performance in high-temperature water is a key factor. The material demonstrates exceptional resistance to corrosion and degradation under the extreme conditions found within a reactor. Key properties include:

- High strength across a wide temperature range.

- Excellent resistance to uniform corrosion and stress-corrosion cracking.

- Superior pitting resistance in water temperatures from 500°F to 600°F (260-316°C).

This combination of features ensures that components maintain their structural integrity for extended service cycles, a crucial requirement for nuclear safety and efficiency.

The alloy’s utility extends beyond current reactor designs. Engineers are considering Inconel 625 for advanced reactor concepts. Its high allowable design strength at even more elevated temperatures, particularly between 1200°F and 1400°F (649-760°C), makes it a prime candidate for next-generation power systems.

This forward-looking potential solidifies the role of Inconel 625 as an indispensable material for the present and future of nuclear energy generation. Its proven endurance provides the ultimate assurance of reliability where it matters most.

Why Choose an Inconel 625 Bar Over Other Alloys?

Selecting the right material is a critical decision that balances performance, fabricability, and cost. While many alloys serve general purposes well, Inconel 625 distinguishes itself as the superior choice for applications where survival is non-negotiable. Its unique properties offer clear advantages over both common stainless steels and other specialized nickel alloys.

Superiority Over Stainless Steels

Stainless steels are valued for their general corrosion resistance and cost-effectiveness in moderate environments. However, their performance diminishes rapidly under extreme heat and aggressive chemical attack. Inconel 625 operates on a different level. It maintains its strength at temperatures that would cause stainless steel to weaken and fail. Its robust resistance to pitting and crevice corrosion in chloride-rich media far surpasses that of standard stainless steels, making it essential for marine and chemical processing industries.

Advantages Compared to Other Nickel Alloys

Even within the family of high-performance nickel alloys, Inconel 625 occupies a unique position. A comparison with Inconel 718, another popular superalloy, highlights these differences. Inconel 718 offers higher tensile strength at moderate temperatures due to its precipitation-hardening nature. Inconel 625, a solid-solution strengthened alloy, provides better overall corrosion resistance and maintains its strength at much higher temperatures.

| Property | Inconel 625 | Inconel 718 |

|---|---|---|

| Max Service Temperature | ~980°C (Low Stress) | ~700°C (High Stress) |

| Tensile Strength (Annealed) | ~880 MPa | ~1035 MPa |

| Yield Strength (Aged) | N/A | ~1140 MPa |

Furthermore, Inconel 625 is renowned for its excellent fabricability and weldability, often requiring less stringent post-weld heat treatments compared to other specialized alloys. This makes it easier and more reliable to construct complex components.

Long-Term Cost-Effectiveness

The initial procurement cost of Inconel 625 is significantly higher than stainless steel. This premium is due to its valuable nickel content and complex manufacturing processes. However, focusing only on the initial price overlooks the total cost of ownership.

For mission-critical components, the whole-life cost of an Inconel 625 Bar is often lower. Its exceptional durability reduces the need for frequent maintenance, repairs, and replacements. This minimizes operational downtime, which can result in substantial financial savings and enhanced safety, justifying the initial investment for long-term reliability.

Fabricating for Survival: Working with Inconel 625

The exceptional properties of Inconel 625 demand specialized fabrication techniques. Its unique metallurgy requires a professional approach to welding, machining, and forming to preserve its inherent strength and corrosion resistance. Following best practices ensures that fabricated components deliver the survival performance expected of this superalloy.

Best Practices for Welding

Inconel 625 offers excellent weldability for a high-performance alloy. It resists post-weld cracking and maintains its properties with proper procedures.

- Routine post-weld heat treatment (PWHT) is generally not required to maintain corrosion performance. The alloy is primarily solid-solution strengthened.

- For specific high-temperature designs or when joining to other materials, fabricators should follow supplier guidance regarding PWHT.

- Solution treatment is an option for particular applications but is not a standard requirement for corrosion resistance.

Pro Tip

When welding thick sections of an Inconel 625 Bar, preheating the material to approximately 300°F (150°C) is advised. This practice helps mitigate the risk of cracking and improves the overall quality of the weld joint.

Guidelines for Machining and Forming

Machining Inconel 625 presents challenges due to its high strength and tendency to work-harden rapidly. Success requires rigid machines, sharp tools, and appropriate parameters.

- For general turning, operators should use tools with a very hard substrate and a thin PVD coating.

- A recommended cutting speed for stable turning is between 60-80 m/min. Using CBN inserts can significantly increase this speed.

Different machining objectives may require different parameters, as shown by various studies.

| Parameter | Objective: Optimal Turning | Objective: Highest Durability |

|---|---|---|

| Cutting Speed | 60 m/min | 250 m/min |

| Feed Rate | 0.1 – 0.3 mm/rev | 0.15 mm/rev |

| Tool Material | Coated Carbide | PCBN (Cubic Boron Nitride) |

The alloy also has excellent forming characteristics. For hot working, fabricators should maintain a temperature between 1800-2150°F (982-1177°C). Completing work at the lower end of this range helps control grain size. The material’s ductility allows for ready cold working, but its rapid work-hardening may require intermediate annealing for complex shapes.

The survival story of an Inconel 625 bar originates from its synergistic alloy composition. This unique blend delivers unmatched performance across hostile environments. Its proven resistance to extreme heat, aggressive corrosion, and intense mechanical stress makes it indispensable in the world’s most demanding industries.

For any application where material failure would be catastrophic, an Inconel 625 bar provides the ultimate assurance of reliability and endurance. This makes it the definitive choice for survival.

FAQ

What makes Inconel 625 a “superalloy”?

Inconel 625 earns its “superalloy” status from its exceptional performance in extreme conditions. Its nickel-based composition provides outstanding strength at high temperatures and superior resistance to corrosion and oxidation. These properties far exceed those of conventional metals, making it a material for survival.

Is Inconel 625 magnetic?

No, Inconel 625 is a non-magnetic nickel-based alloy. This characteristic is important for specialized applications in electronics, subsea equipment, and other fields where magnetic interference must be avoided. Its non-magnetic nature remains stable even after extensive cold working.

What are the main differences between Inconel 625 and stainless steel?

Inconel 625 provides significantly better performance than stainless steel in harsh environments. It maintains its strength at temperatures that weaken stainless steel. It also offers far greater resistance to pitting and crevice corrosion, especially in chloride-rich settings like seawater.

What are the common forms of Inconel 625?

This versatile alloy is available in several product forms to suit various industrial needs. While the bar is a primary focus, other common shapes ensure broad applicability. These include:

- Inconel 625 Round Bar

- Inconel 625 Hex Rod

- Inconel 625 Flat Bar

- Inconel 625 Square Bar

See Also

Optimizing Steel Processing for Heat Exchangers: Consistent Performance Guaranteed

Future-Proofing: Expert Welding Techniques for 2025 Pass Partition Plates

Unlocking Superior TIG Welding: Essential Facts About WT20 Electrodes

Understanding Molybdenum High-Temperature Furnaces: Design and Operational Insights

Assessing Molybdenum Plugs for Seamless Steel Pipe Manufacturing in 2025

Post time: Dec-23-2025