Nickel Alloy 59 Welding Wire

Alloy 59 Nickel Alloy Welding Wire is a high-performance nickel-chromium-molybdenum welding consumable designed for exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking.

It corresponds to UNS N06059 / EN 2.4605 and is commonly classified as ERNiCrMo-13.

Alloy 59 welding wire offers excellent weldability, high thermal stability, and outstanding corrosion resistance in highly aggressive environments, including oxidizing and reducing media.

| Specifications of Nickel Alloy 59 wire: |

| Specifications | AWS A5.14 |

| Grade | Alloy 59 |

| Wire diameter | 0.50 mm to 10 mm |

| Type | Wire Bobbin, Wire Coil, Filler Wire, Coils, Wiremesh |

| Surface | Black, Bright, Polished |

| Delivery state | Soft annealed – ¼ hard, ½ hard, ¾ hard, full hard |

| Nickel 59 Wire Equivalent Grades: |

| STANDARD | WERKSTOFF NR. | UNS |

| Alloy 59 | – | N06059 |

| Inconel X-750 nickel alloy wire Chemical Composition and Mechanical properties: |

| Ni | Fe | C | Mn | Si | Al | S | P | Cr | Co | Cu | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|

| - | 1.5 | 0.08 | 0.5 | 0.150 | 0.10-0.4 | 0.01 | 0.015 | 22.0-24.0 | 0.3 | 0.5 | 15-16.5 |

| Tensile strength | 101,500 PSI | 700 MPA |

| Yield strength | 85,000 PSI | 400MPA |

| Elongation | 30% |

| Welding parameters: |

| Process | Diameter | Voltage | Amperage | Gas |

| TIG | .035” (0.9mm) .045” (1.2mm) 1/16” (1.6mm) 3/32” (2.4mm) 1/8” (3.2mm) |

12-15 13-16 14-18 15-20 15-20 |

60-90 80-110 90-130 120-175 150-220 |

100% Argon 100% Argon 100% Argon 100% Argon 100% Argon |

| MIG | .035” (0.9mm) .045” (1.2mm) 1/16” (1.6mm) |

26-29 28-32 29-33 |

150-190 180-220 200-250 |

75% Argon + 25% Helium 75% Argon + 25% Helium 75% Argon + 25% Helium |

| SAW | 3/32” (2.4mm) 1/8” (3.2mm) 5/32” (4.0mm) |

28-30 29-32 30-33 |

275-350 350-450 400-550 |

Can be used with appropriate flux Can be used with appropriate flux Can be used with appropriate flux |

| Key Features Alloy 59 Nickel Alloy Welding Wire : |

-

Excellent resistance to pitting, crevice and stress corrosion cracking

-

Superior performance in chloride-containing and mixed acid environments

-

High weld integrity with stable arc and low spatter

-

Good ductility and strength after welding

-

Suitable for TIG (GTAW) and MIG (GMAW) welding processes

| Applications high strength alloy wire : |

-

Chemical processing equipment exposed to strong acids and chlorides

-

Oil & gas and petrochemical pipelines under high corrosion conditions

-

Offshore and marine structures in seawater environments

-

Flue Gas Desulfurization (FGD) and environmental protection systems

-

Dissimilar metal welding between nickel alloys and stainless steels

| FAQ : |

Q1: What is Alloy 59 welding wire used for?

A: It is mainly used for welding nickel-based alloys and dissimilar metals exposed to severe corrosion conditions.

Q2: Is Alloy 59 welding wire suitable for seawater applications?

A: Yes, Alloy 59 shows excellent resistance to chloride-induced corrosion, making it ideal for marine environments.

Q3: What welding methods are suitable?

A: TIG (GTAW) and MIG (GMAW) welding methods are commonly recommended.

| Why Choose Us : |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

| Sasa alloy’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

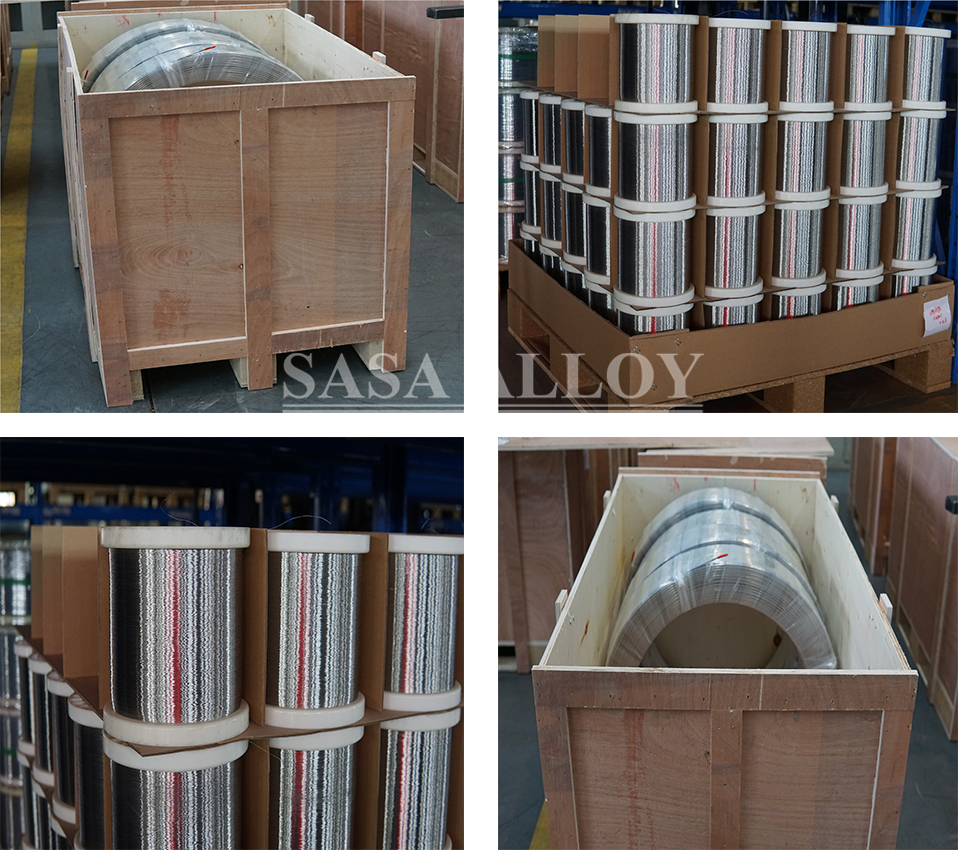

| Sasa alloy’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa alloy’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,