Achieving superior quality for the Inconel 625 Bar in 2025 requires an integrated manufacturing approach. Advanced forging methods, like isothermal and multi-directional forging, create a refined starting grain structure. This superior microstructure is then paired with innovative machining strategies. These techniques directly manage extreme heat and reduce work hardening. For example, cryogenic cooling with liquid nitrogen can improve surface roughness by over 31% compared to dry cutting. This combination of intelligent forging and advanced machining delivers exceptional surface integrity and dimensional accuracy for final components.

Key Takeaways

- Start with good material. Advanced forging makes Inconel 625 stronger and easier to cut.

- Use special cutting methods. Cryogenic cooling and laser heating help cut Inconel 625 better.

- Pick the right tools. Strong tools like PCBN and coated carbides last longer when cutting tough Inconel 625.

- Control how you cut. High-pressure coolant and careful speed settings make the cutting process smooth.

- Use smart technology. AI helps machines predict problems and work better, making sure every part is high quality.

Advanced Forging for a Superior Starting Microstructure

The journey to a flawless machined component begins long before the cutting tool touches the material. Advanced forging techniques create a superior starting microstructure. This initial step is crucial for mitigating the inherent machining challenges of nickel-based superalloys. A refined, uniform grain structure established during forging directly improves machinability, reduces tool wear, and enhances the final mechanical properties of the part.

Isothermal and Hot-Die Forging

Isothermal forging represents a significant leap over conventional methods. The process maintains a constant, elevated temperature for both the workpiece and the die. This precise thermal control yields several key advantages for high-performance alloys:

- Grain Structure Control: The stable temperature promotes the formation of fine, uniform grain sizes. This optimized microstructure enhances strength and fatigue resistance.

- Defect Reduction: It minimizes internal defects like voids, porosity, and cracks that can compromise material integrity.

- Enhanced Mechanical Properties: The resulting material shows superior durability and is more resistant to stress and deformation, extending its service lifespan.

Multi-Directional Forging (MDF)

Multi-Directional Forging (MDF) takes grain refinement to the next level. This method involves deforming the material sequentially along three orthogonal axes. Each pass breaks down coarse grain structures further. The result is an exceptionally fine and homogenous microstructure throughout the entire Inconel 625 Bar. This uniformity is critical for predictable machining, as it eliminates inconsistencies that can lead to unpredictable tool wear and surface flaws.

Advanced Post-Forging Heat Treatments

Forging is only part of the equation. Advanced post-forging heat treatments lock in the microstructural benefits achieved.

Processes like solution annealing and aging are meticulously controlled. They relieve internal stresses induced during forging and stabilize the refined grain structure. This final preparatory step ensures the workpiece is in its optimal condition, ready for precision machining operations without the risk of distortion or unexpected material behavior.

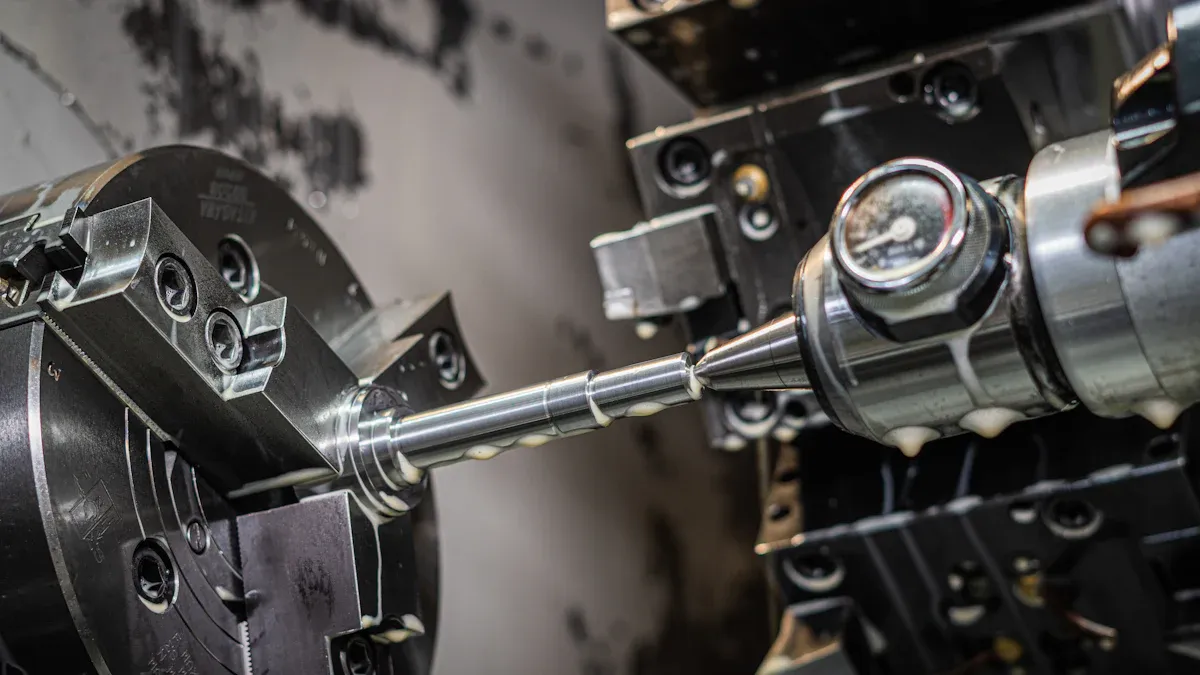

Cutting-Edge Machining Strategies for the Inconel 625 Bar

Even with a superior forged microstructure, machining Inconel 625 presents significant hurdles due to its high strength at elevated temperatures and tendency to work-harden. Traditional machining methods often result in rapid tool wear, poor surface finish, and dimensional inaccuracies. The 2025 manufacturing landscape overcomes these issues by adopting intelligent, thermally-managed machining strategies that control the cutting environment.

Cryogenic Machining

Cryogenic machining introduces an ultra-cold medium, such as liquid nitrogen (LN2) or liquid carbon dioxide (LCO2), directly into the cutting zone. This process fundamentally changes the material’s interaction with the cutting tool. The extreme cooling action provides a powerful defense against the intense heat generated during machining.

Cryogenic cooling with LN2 significantly reduces the temperature at the tool-chip interface. This prevents the thermal softening of the tool and mitigates the formation of chip weldments on the cutting edge. By lowering friction and temperature, this method effectively lessens adhesive wear and abrasive wear. These are two of the primary tool failure mechanisms when machining nickel-based superalloys.

Note: The benefits are quantifiable. Studies show that using liquid CO2, a form of cryogenic cooling, can reduce tool wear by as much as 35% when drilling Inconel 625 compared to conventional lubrication methods. This extends tool life and improves process reliability.

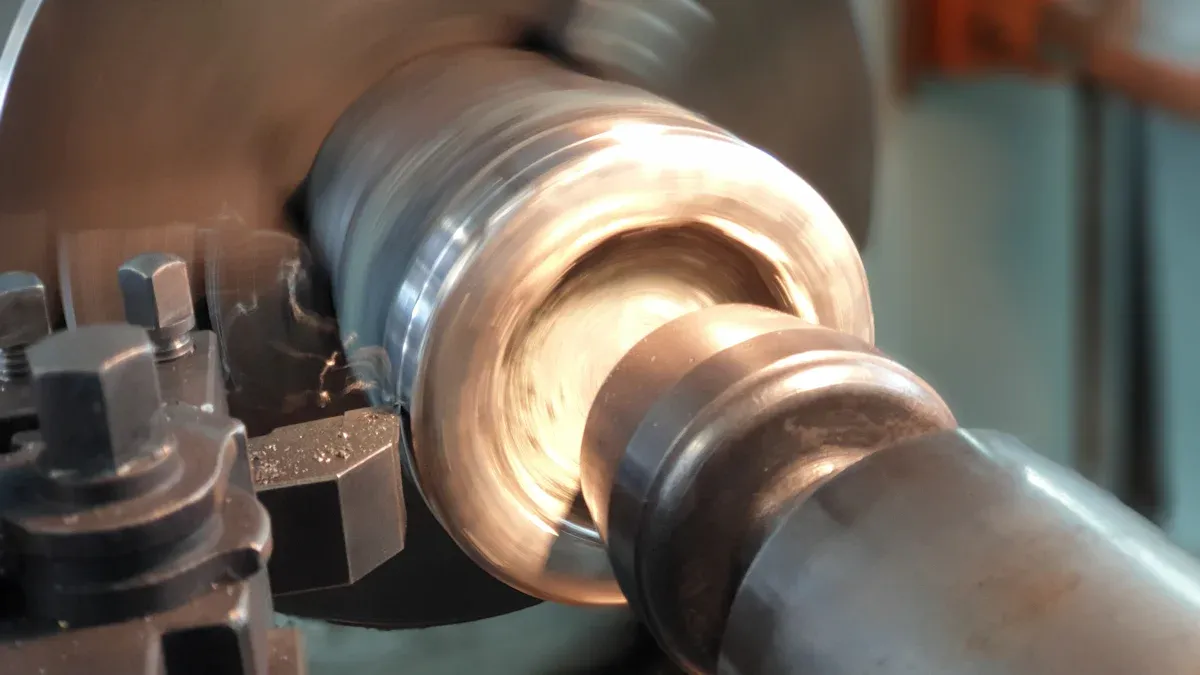

Laser-Assisted Machining (LAM)

Laser-Assisted Machining (LAM) takes a counterintuitive yet highly effective approach. Instead of fighting the heat, it uses a precisely focused laser beam to intentionally heat and soften a localized area of the workpiece just ahead of the cutting tool. This pre-heating action dramatically enhances the material’s workability, making it easier to remove.

The advantages of this localized thermal softening are substantial:

- It significantly reduces the cutting forces required to shear the material.

- It leads to a smoother, more precise cut with improved surface roughness.

- It minimizes subsurface damage and the work-hardening effect common in conventional turning.

Analysis of tool wear in Laser-Assisted Turning (LAT) shows only abrasion and flaking. This contrasts sharply with conventional methods, which also exhibit severe cratering and edge chipping. The data clearly demonstrates the effectiveness of LAM.

| Parameter | Reduction vs. Conventional Turning |

|---|---|

| Cutting Force (Fx) | 20% |

| Cutting Force (Fy) | 17% |

| Cutting Force (Fz) | 30% |

| Maximum Flank Wear (VBmax) | 18% |

| Surface Roughness (Ra) | 16% |

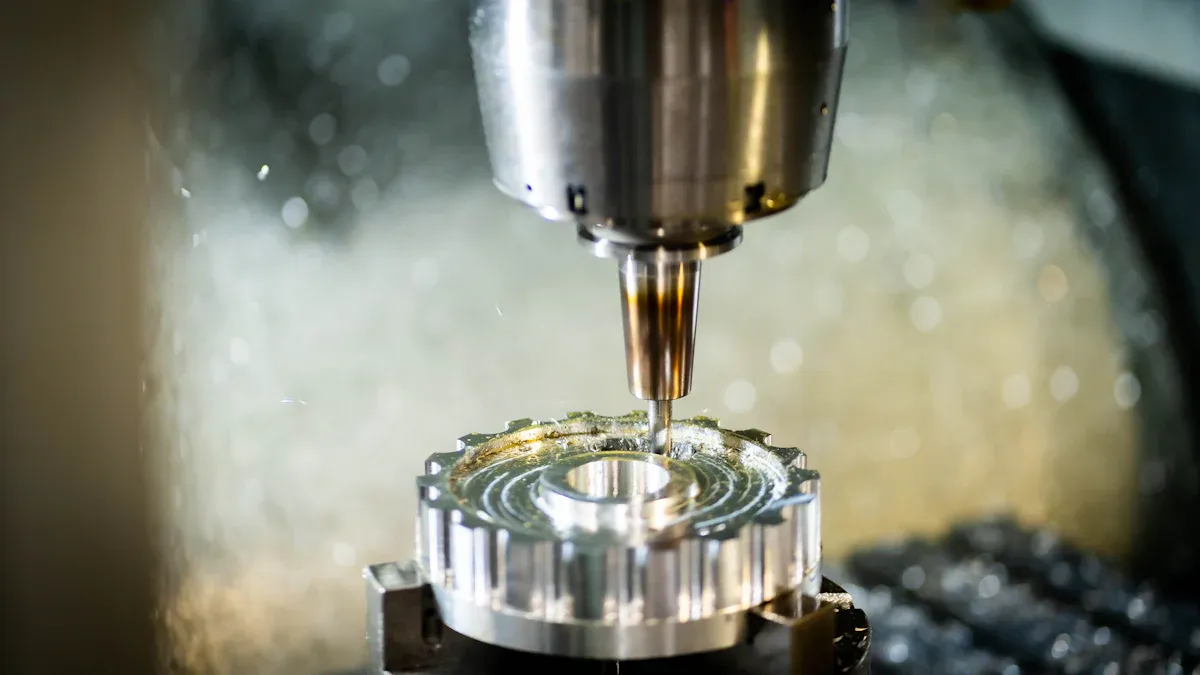

Advanced Tooling: PCBN and Coated Carbides

The right strategy requires the right tools. For an Inconel 625 Bar, advanced tooling materials are not optional—they are essential for success. Polycrystalline Cubic Boron Nitride (PCBN) and specially coated carbides are the leading choices for high-performance machining.

Coated Carbide InsertsCarbide tools remain a versatile and cost-effective option, especially when enhanced with advanced coatings. These tools use treatments like Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) to apply a thin, hard layer to the tool surface. For machining Inconel alloys, tools with a hard coating like TiAlN are necessary to retain tool hardness at high cutting temperatures.

| Tool Type | Material / Grade | Typical Coatings | Application |

|---|---|---|---|

| Carbide (solid & indexable) | Submicron/high-Co carbide | PVD AlTiN / TiAlN / AlCrN; CVD TiCN/TiN | General milling & turning. |

PCBN ToolingPCBN is a super-hard material second only to diamond in hardness. It offers exceptional thermal stability and wear resistance, making it ideal for finishing operations on tough superalloys. However, understanding its failure modes is key to optimizing its use. Adhesion, built-up edge (BUE), and chipping are common wear mechanisms at lower depths of cut. At higher axial depths, tool fracture can occur. Furthermore, flank wear often becomes the dominant failure mode at high cutting speeds, while notch wear is more prevalent at lower speeds. Careful selection of cutting parameters and tool geometry is critical to harnessing PCBN’s full potential and avoiding premature tool failure.

Optimizing Cutting Parameters and Environment

Advanced strategies and tooling are only effective when paired with a precisely controlled cutting environment. Optimizing coolant delivery and machining parameters is essential for managing heat, controlling chip formation, and ensuring process stability when working with the Inconel 625 Bar.

High-Pressure Coolant (HPC) Systems

High-Pressure Coolant (HPC) systems deliver a focused, high-velocity stream of fluid directly to the cutting zone. This method is far more effective than traditional flood cooling. For optimal chip breaking and thermal control, systems should operate at pressures of 70 bar (over 1000 PSI) or greater. This intense pressure provides several key advantages:

- Enhanced Chip Evacuation: The powerful jet effectively breaks and flushes away the tough, stringy chips characteristic of Inconel 625.

- Improved Cooling Efficiency: HPC penetrates the vapor barrier that forms at the tool-chip interface, drastically reducing cutting temperatures.

- Longer Tool Life: By minimizing heat and preventing chip recutting, HPC significantly extends the lifespan of expensive cutting tools.

Minimum Quantity Lubrication (MQL)

Minimum Quantity Lubrication (MQL) represents a shift towards sustainable and efficient manufacturing. This technique delivers a fine aerosol of lubricant and compressed air to the cutting point, drastically reducing fluid consumption compared to flood systems.

MQL is a “cleaner technology” that addresses the environmental and health risks associated with bulk fluid disposal. It serves as a futuristic model for green manufacturing by minimizing waste and operational expenses, making it a cost-effective machining process.

Studies show MQL with graphene-enhanced nanofluids outperforms flood cooling in surface finish and tool life. For these systems, biodegradable fluids like vegetable-based oils and synthetic esters are recommended for their high lubricity and stability.

Optimizing Speeds, Feeds, and Depth of Cut

Fine-tuning cutting parameters is the final piece of the optimization puzzle. An incorrect parameter can negate the benefits of advanced tooling and cooling. For Inconel 625, a conservative approach often yields the best results.

Implementing a shallower depth of cut is a proven strategy for enhancing efficiency and prolonging tool life. A smaller depth reduces the mechanical load and heat accumulation on the cutting edge. For example, a depth of cut of 0.5 mm has been shown to reduce cutting forces and wear. This parameter also helps produce manageable chips, which improves surface quality and simplifies chip evacuation.

| Parameter | Recommendation | Rationale |

|---|---|---|

| Cutting Speed | Low to moderate | Prevents excessive heat generation and tool wear. |

| Feed Rate | Consistent and moderate | Avoids work hardening and ensures stable cutting. |

| Depth of Cut | Shallow (e.g., 0.5 mm) | Reduces tool load and improves chip control. |

Integrating AI and Monitoring for Quality Assurance

Modern manufacturing elevates quality assurance from a post-production check to an intelligent, in-process system. Integrating Artificial Intelligence (AI) and real-time monitoring transforms Inconel 625 bar machining. This approach creates a self-correcting environment that predicts issues, optimizes performance, and guarantees component integrity from the very first cut.

In-Process Sensing and Adaptive Control

In-process sensing provides the machine with real-time “eyes and ears” during operation. Advanced sensors continuously collect critical data to monitor the health of the cutting process. This data allows adaptive control systems to make immediate adjustments, preventing tool failure and ensuring consistent quality.

Key data sources for monitoring tool wear include:

- Spindle Power Data: Collected directly from the machine’s power meter, this data offers a reliable way to track tool wear and detect potential breakage.

- Force Data: Dynamometers measure cutting forces, providing trends that mirror spindle power data and confirm the state of the tool.

- Acoustic and Vibration Signals: These signals offer partial information about the machine’s condition, helping predict surface quality and identify issues like imbalance or bearing wear.

An adaptive control system analyzes this incoming data and automatically optimizes machining parameters. For instance, a system using a neural controller and Grey Wolf Optimization (GWO) can adjust speed and feed to minimize wear, demonstrating a 12% improvement in tool life compared to conventional methods.

AI for Predictive Maintenance and Optimization

AI takes process monitoring a step further by enabling predictive capabilities. Machine learning (ML) algorithms analyze vast amounts of sensor data to identify complex patterns that precede tool wear or failure. This allows manufacturers to forecast the remaining useful life (RUL) of a cutting tool with remarkable accuracy.

Various machine learning techniques, including Support Vector Machines (SVM), K-Nearest Neighbors (KNN), and Random Forest (RF), are applied for this purpose. These models process real-time vibration and sound signals to evaluate tool condition. They can also predict key outputs like cutting forces and surface roughness, which are direct indicators of machinability and wear. By predicting when a tool will fail, AI facilitates proactive maintenance scheduling, minimizes unexpected downtime, and maximizes the operational efficiency of machining the Inconel 625 bar.

Achieving peak quality for the Inconel 625 Bar in 2025 requires a holistic strategy. This integrated approach begins with a precisely forged microstructure from methods like Isothermal and Multi-Directional Forging. It finishes with controlled machining using Cryogenic, LAM, and PCBN tooling. Adopting this definitive path overcomes Inconel’s challenges, maximizing performance and efficiency. Success is measured by key improvements in:

- Surface integrity and roughness

- Material removal rate

FAQ

Why is advanced forging crucial for machining Inconel 625?

Advanced forging creates a refined, uniform grain structure. This superior microstructure improves the material’s machinability. It reduces unpredictable tool wear and enhances the final component’s mechanical strength, ensuring a more efficient and reliable process.

What is the main benefit of Cryogenic Machining?

Cryogenic machining uses liquid nitrogen to drastically cool the cutting zone. This process minimizes heat-related tool wear. It also improves surface finish and extends tool life, which are critical for machining tough superalloys like Inconel 625.

Which cutting tool is best for finishing Inconel 625?

PCBN (Polycrystalline Cubic Boron Nitride) tools are ideal for finishing operations. Their exceptional hardness and thermal stability allow for high-speed finishing. This results in superior surface integrity and dimensional accuracy on the final Inconel 625 component.

How does AI improve the machining process?

AI uses sensor data to predict tool failure and optimize cutting parameters in real time. This predictive capability minimizes downtime. It also ensures consistent quality and maximizes the operational efficiency of the entire machining workflow for the Inconel 625 bar.

What are the key specifications for Inconel 625 bar?

Inconel 625 bar is a nickel-based superalloy with excellent corrosion resistance. Key designations include:

- UNS: N06625

- Material No.: 2.4856

- AMS: 5666

- ASTM: B446

It is a non-magnetic material ideal for lower-temperature applications where its corrosion resistance excels.

See Also

Assessing Molybdenum Plugs for Seamless Steel Pipe Manufacturing in 2025

Exploring Molybdenum High-Temperature Furnace Technology and Applications in 2025

Professional Guidance for Welding Pass Partition Plates Effectively in 2025

Optimizing Steel Processing for Superior Heat Exchange Performance and Results

Essential WT20 Thoriated Tungsten Electrode Insights for Enhanced TIG Welding

Post time: Dec-23-2025