The Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876 1.4959 Nickel-Based Alloy family is a critical material group in a market projected to reach USD 23.78 billion by 2030. The primary distinctions among these alloys involve tightly controlled levels of Carbon (C), Aluminum (Al), and Titanium (Ti). These chemical variations, combined with specific heat treatments, directly determine the high-temperature strength and creep resistance of products like an Incoloy 800 Bar.

Key Takeaway: N08800 is the foundational alloy, while N08810 and N08811 offer enhanced properties for progressively more demanding high-temperature applications.

Key Takeaways

- UNS N08800 is the basic alloy. It works well for temperatures below 1100°F (600°C).

- UNS N08810 (800H) has more carbon. It is better for temperatures above 1100°F (600°C). It resists bending over time.

- UNS N08811 (800HT) has the most strength. It works best for very high temperatures, above 1300°F (700°C).

- The main differences are in the carbon, aluminum, and titanium levels. Special heat treatments also make them stronger.

- Many products are ‘dual-certified’ as 800H/HT. This means they meet the highest standards for both alloys.

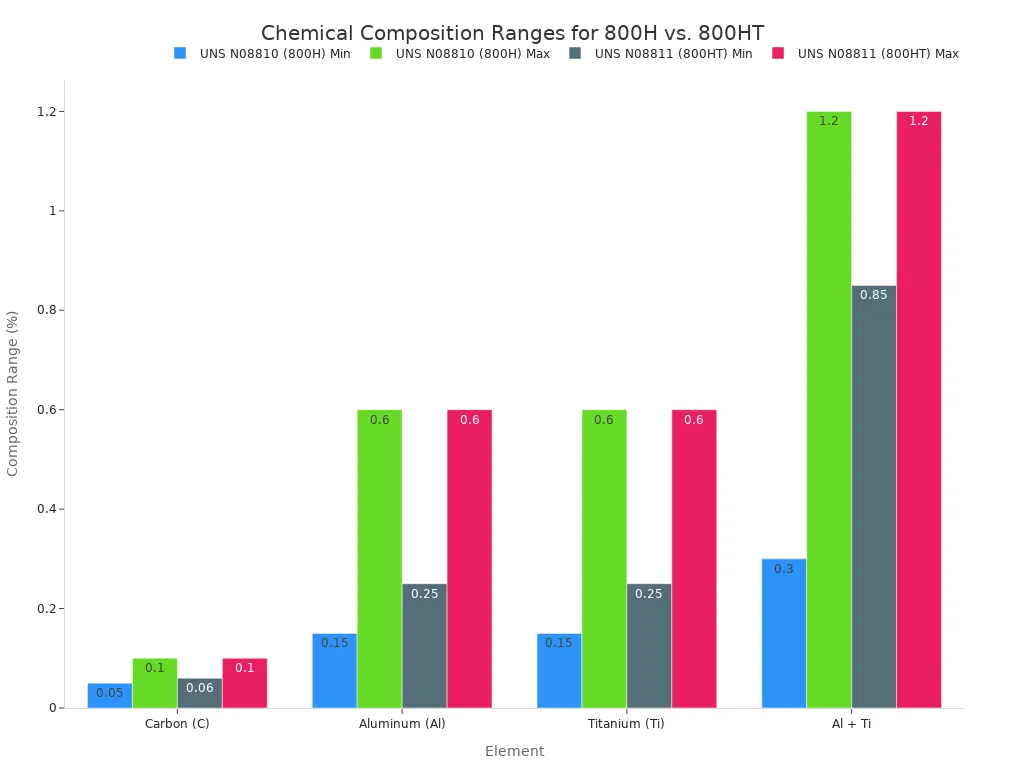

Chemical Composition: The Defining Factor

The fundamental properties of these nickel-iron-chromium alloys are established by their chemistry. While all three grades share a similar base composition, minor adjustments in specific elements create significant performance differences, particularly at elevated temperatures. These controlled variations are the primary reason for their distinct UNS designations.

UNS N08800 (Incoloy 800): The Foundation

UNS N08800 serves as the base alloy for this series. It provides excellent resistance to oxidation and carburization, along with good tensile strength. Its chemical makeup offers a robust and versatile material for general high-temperature service. The typical composition provides a solid foundation of nickel, chromium, and iron.

| Element | Composition % (Alloy 800 / UNS N08800) |

|---|---|

| Nickel | 30.0-35.0 |

| Chromium | 19.0-23.0 |

| Iron | 39.5 min |

| Carbon | 0.10 max |

| Aluminum + Titanium | 0.30-1.20 |

This chemistry gives the alloy reliable strength and ductility for applications generally below 1100°F (600°C).

UNS N08810 (Incoloy 800H): Enhanced Creep Resistance

UNS N08810, or Incoloy 800H, represents a targeted enhancement of the base alloy. The key modification involves a tighter control over carbon content. This change directly improves the material’s high-temperature properties, especially creep and rupture strength.

Specification Note: According to ASTM B409, the carbon content for Alloy UNS N08810 must be within the range of 0.05% to 0.10%.

This higher carbon level, combined with a solution annealing heat treatment, results in a coarser grain structure that is more resistant to deformation over time at high temperatures.

UNS N08811 (Incoloy 800HT): Optimized for Maximum Strength

UNS N08811 takes high-temperature performance a step further. This grade maintains the higher carbon level of N08810 but adds even stricter controls on the combined aluminum (Al) and titanium (Ti) content. The specification for this Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876 1.4959 Nickel-Based Alloy requires the Al + Ti content to be between 0.85% and 1.20%. This precise chemical balance, coupled with a high-temperature anneal, optimizes the alloy for the most demanding applications requiring maximum rupture and creep strength at temperatures exceeding 1100°F (600°C).

Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876 1.4959 Nickel-Based Alloy Performance

The performance of these alloys at high temperatures is not solely dependent on their chemical composition. Specific heat treatment protocols unlock the full potential of grades N08810 and N08811, creating distinct microstructural characteristics that directly translate to superior mechanical properties under thermal stress.

Heat Treatment and Grain Size

Heat treatment is the critical processing step that differentiates the performance of Alloy 800 from its 800H and 800HT counterparts. While UNS N08800 is typically supplied in a mill-annealed condition, N08810 and N08811 undergo a high-temperature solution anneal. This process serves a dual purpose: it dissolves carbides and develops a specific grain structure essential for high-temperature strength.

According to ASTM standards, the minimum solution annealing temperature for UNS N08810 is 2050°F (1121°C). The specification for UNS N08811 is even more stringent, requiring a minimum annealing temperature of 2100°F (1149°C). This high-temperature treatment promotes the development of a coarse grain structure. The industry standard for both alloys is a grain size that meets or exceeds a specific threshold.

| UNS Designation | Incoloy Alloy | Target ASTM Grain Size |

|---|---|---|

| N08810 | 800H | 5 or Coarser |

| N08811 | 800HT | 5 or Coarser |

A coarse grain structure is fundamental to achieving high-temperature strength. Extensive research confirms that a larger grain size significantly improves performance.

The reason for this is clear: Increasing grain size reduces grain boundary sliding, which is a primary mechanism of creep at high temperatures. In coarse-grained materials, there are fewer grain boundaries to slide past one another, forcing deformation to occur through less efficient mechanisms.

Creep and Rupture Strength Comparison

The combination of controlled carbon content and a coarse grain structure gives the Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876 1.4959 Nickel-Based Alloy grades N08810 and N08811 significantly higher creep and rupture strength compared to the base N08800 alloy. While their mechanical properties are similar at lower temperatures, the performance gap widens dramatically as service temperatures rise above 1100°F (600°C).

The higher carbon in 800H and 800HT precipitates as carbides along the grain boundaries, which helps to pin them in place and resist movement under load. This microstructural advantage is reflected in the material’s design allowable stress values. For applications involving long-term exposure to high stress and temperature, 800H and 800HT provide a much greater margin of safety against deformation and failure. The table below shows typical stress-rupture values, illustrating the capability of these enhanced grades.

| Alloy | Temperature (°F) | Temperature (°C) | 10,000 h Creep Rupture Strength (ksi) | 10,000 h Creep Rupture Strength (MPa) |

|---|---|---|---|---|

| 800H/800HT | 1400 | 760 | 7.0 | 48 |

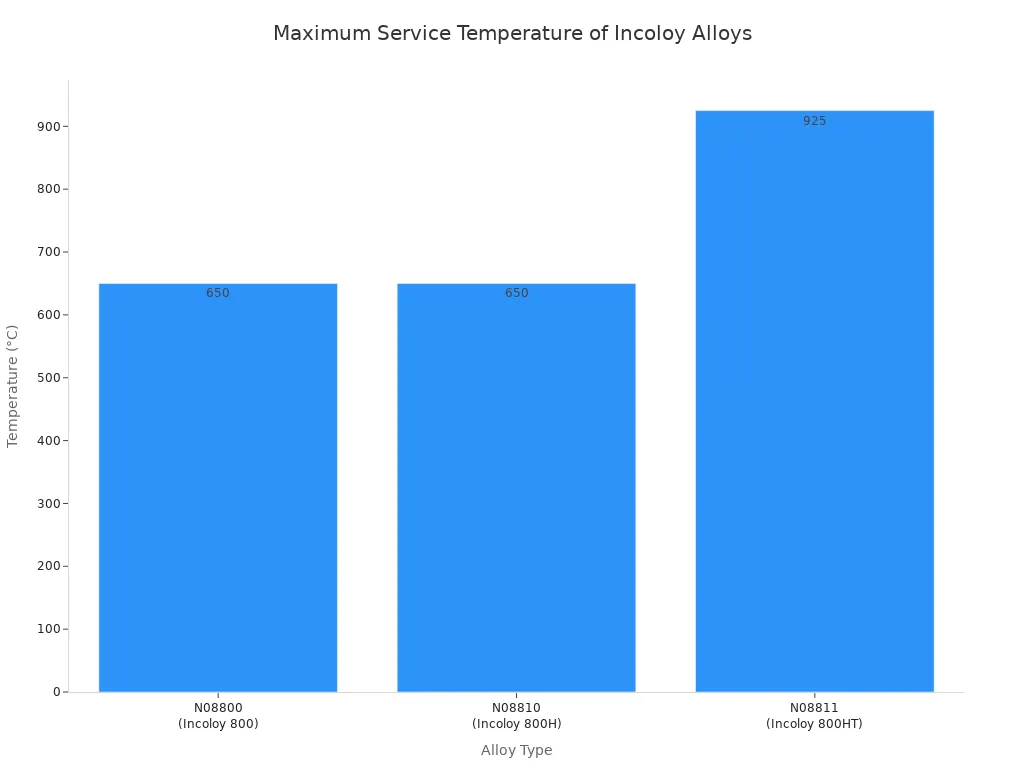

Recommended Service Temperatures

Selecting the correct alloy grade is crucial for ensuring both safety and cost-effectiveness. Each material is optimized for a specific operational window.

- UNS N08800 (Incoloy 800): This is the standard choice for applications operating at temperatures generally below 1100°F (600°C). It provides excellent oxidation and corrosion resistance where high creep strength is not the primary design requirement.

- UNS N08810 (Incoloy 800H): This grade is intended for service above 1100°F (600°C). Its controlled carbon content and coarse grain structure provide the necessary creep and rupture strength for components like industrial furnace parts, headers, and process piping.

- UNS N08811 (Incoloy 800HT): This alloy is optimized for the most demanding conditions, typically above 1300°F (700°C). The tighter control over aluminum and titanium content, combined with the high-temperature anneal, delivers the maximum possible creep and rupture strength for critical applications like ethylene furnace quench boilers and pigtails.

Application and Selection Guide

Making an informed material selection between UNS N08800, N08810, and N08811 is essential for ensuring operational integrity, safety, and cost-effectiveness. The choice depends entirely on the specific demands of the application, primarily the service temperature and mechanical stress levels.

Choosing the Right Alloy

Engineers must evaluate the key performance indicators for each grade to match the material to the environment. While all three alloys share excellent general corrosion resistance, their high-temperature capabilities differ significantly.

Selection Tip: For applications operating below 650°C (1202°F), N08800 is often the most cost-effective and durable choice. Service environments that continuously exceed this temperature require the enhanced creep properties of N08810 or N08811.

The following table provides a clear comparison of the primary selection criteria:

| Property / Environment | N08800 (Incoloy 800) | N08810 (Incoloy 800H) | N08811 (Incoloy 800HT) |

|---|---|---|---|

| Maximum Service Temperature | Up to 650°C | Above 650°C | Up to 925°C |

| High-Temp Tensile Strength | Good | Improved | Superior |

| Creep Resistance | Moderate | Improved | Highest |

| Corrosion Rate (Acetic Acid 10%) | 0.0003 mm/year | Similar to N08800 | Similar to N08800 |

The superior high-temperature performance of N08811 is a direct result of its tightly controlled chemistry and specialized heat treatment.

When environments involve aggressive atmospheres or demand maximum resistance to creep, N08811 provides the best long-term stability and performance.

Understanding Dual Certification (800H/HT)

In the marketplace, it is common to find material labeled as “800H/HT” or dual-certified to both UNS N08810 and N08811 specifications. This practice offers significant advantages for both manufacturers and end-users.

A material receives dual certification when its chemical composition and mechanical properties meet the strictest requirements of both standards.

Manufacturers prefer this approach for several key reasons:

- Simplified Inventory: It reduces the need to stock two separate grades of material, streamlining inventory management and reducing costs.

- Supply Chain Efficiency: This strategy minimizes the number of distinct material grades that need to be sourced, tracked, and managed.

- Greater Flexibility: A single dual-certified product can serve a wider range of applications, offering greater versatility to fabricators and engineers.

To achieve dual certification, a heat of the alloy must meet the most restrictive chemical limits of both specifications. Specifically, the carbon content must be between 0.06% and 0.10%, and the combined aluminum and titanium content must fall within the narrow 0.85% to 1.20% range required by N08811.

Common Industry Applications

The unique properties of the Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876 1.4959 Nickel-Based Alloy family make these materials indispensable in several demanding industries. Their ability to withstand high temperatures, stress, and corrosive environments leads to their use in critical components.

Common applications include:

- Petrochemical Processing: N08810 and N08811 are extensively used for ethylene pyrolysis furnace coils and pigtails. They also see service in cracking furnaces for producing vinyl chloride, diphenol, and acetic acid.

- Power Generation: The alloys are a standard material for superheater and reheater tubing in power plants. The formation of a durable chromium oxide (Cr2O3) layer provides excellent protection against oxidation and carburization at elevated temperatures. Studies show an acceptable corrosion rate even under simulated supercritical water conditions.

- Industrial Heating: Components like headers, manifolds, and radiant tubes in industrial furnaces benefit from the high-temperature strength and resistance to thermal cycling offered by 800H and 800HT.

- Nuclear Engineering: Alloy 800H is specified for certain nuclear reactor components due to its combination of strength, structural stability, and resistance to oxidation in high-temperature environments.

In summary, selecting the correct Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876 1.4959 Nickel-Based Alloy hinges on the service temperature and required mechanical properties.

- N08800 is the standard choice for applications below 1100°F (600°C).

- N08810 (800H) provides greater creep and rupture strength above 1100°F (600°C) due to its higher carbon content and specialized heat treatment.

- N08811 (800HT) offers maximum strength for the most extreme temperatures through tightly restricted chemistry.

Practical Tip: Most modern high-temperature applications utilize dual-certified 800H/HT material. This simplifies inventory and guarantees performance by meeting the strictest requirements of both N08810 and N08811.

ASME Code Cases, such as the ones below, govern the use of these alloys in critical pressure vessel applications.

| Material (UNS) | Form | ASME Code Case |

|---|---|---|

| N08810 (Alloy 800H) | Pipe | 1325, 1983 |

| N08810 (Alloy 800H) | Strip | 1325, 2339 |

FAQ

What is the primary difference between Incoloy 800 and 800H?

UNS N08810 (800H) contains a higher, controlled carbon level (0.05-0.10%). This specific chemistry, combined with a solution anneal, gives it significantly better creep and rupture strength for service above 1100°F (600°C) compared to the base N08800 alloy.

Why is dual-certified 800H/HT material so common?

Dual certification simplifies inventory for suppliers and provides maximum flexibility for users. A single product meets the strictest chemical and heat treatment requirements of both N08810 and N08811 specifications, guaranteeing top-tier performance for a wide range of high-temperature applications.

Can UNS N08800 be used in high-temperature creep applications?

No, engineers do not recommend UNS N08800 for applications where creep resistance is critical. It lacks the specific carbon control and coarse grain structure of N08810 and N08811, which are essential for resisting deformation under long-term thermal stress.

What makes UNS N08811 the strongest of the three alloys?

UNS N08811 achieves the highest strength through the tightest controls. It requires a higher carbon content, a restricted aluminum and titanium range (0.85-1.20%), and a high-temperature anneal. This precise combination optimizes its microstructure for maximum performance at the most extreme temperatures.

Post time: Jan-06-2026