ASTM B865 Monel K500 Round Bar – Corrosion-Resistant Alloy Stock

Monel K500 round bar supplier, Monel K500 Flat Bar, Monel K500 Hex Bar Suppliers in China, Monel K500 Rod, Alloy K500 Hollow Bar Stockist in China, Monel Alloy K500 Round Rod distributor, Monel K500 round bar manufacturer in China.Monel K500 Round Bar is designated as UNS N05500 and Werkstoff Number 2.4375. Alloy K500 Round Bar are known as Monel K-500 Round Bar, Monel Alloy K500 Round Bar & Nickel Alloy K500 Round Bar. Alloy K500 Round Bar, Monel K500 Flat Bar and Monel K500 Hex Bar has a greater tendency toward stress-corrosion cracking in some environments than Monel 400 bar.

| Monel K500 round bar Specification: |

| Grade | Monel K500 – UNS N05500 |

|---|---|

| Specification | ASTM B865 UNS N05500, ASTM B 865 / ASME SB 865 / AMS 4676 / QQ N 286 |

| Monel K500 Round bar size | Diameter: 3mm~800mm |

| Monel K500 Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Monel K500 Square bar size | 4mm*4mm~100mm*100mm |

| Monel K500 Flat bar size | Thickness: 2mm~100mm |

| Width: 10mm~500mm | |

| Monel K500 Hex Bar size | 2mm~100mm |

| Monel K500 Billet Size | 1/2" to 495mm Diameter |

| Monel K500 Rectangles Size | 33mm x 30mm to 295mm x 1066mm |

| Monel K500 Round Bar Standard Dimensions | As the customer required |

| Finish | Bright, Polish, Bright, Rough Turned, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Annealed round bar |

| Technique | Monel K500 Hot Rolled, Cold Rolled, Cold Drawn, Forged Round Bar, Rod |

| Monel K500 Bar Type | Drawn Bar, Rolled Bar, Forged Bar, GFM Forged Bar, Open Die Bar, Forged Stepped Shafts, Forged Flat Bar, Forged Square Bar |

| Also Check price list of | Inconel Round Bar, Inconel 625 Round Bar, Inconel 718 Round Bar, Hastelloy Round Bar, Monel Round Bar, Titanium Round Bar, Copper Nickel Bar, Stainless Steel Round Bar |

| Form | Round, Rod, Precision Ground Bar, Square, Round Rod, Hollow, Hex (A/F), Triangle, Rectangle, Threaded, T-Bar, Half Round Bar, Flat Bar, Rings, Blocks, Billet, Ingot, I/H Bar, Angle, Channel Bar, Profiles, Forging Etc. |

| Monel Alloy K500 Bar Chemical Composition: |

| Grade | Ni | Fe | C | Mn | Si | Cu | Al | S | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Monel K500 | 63.0 min | 0.5 – 2 | 0.25 max | 1.5 max | 0.5 max | 27.0 – 33.0 | 2.3 – 3.15 | 0.010 max | 0.35 – 0.85 |

| AMS 4676 Monel K500 Bar Equivalent Grades: |

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Monel K500 | 2.4375 | N05500 |

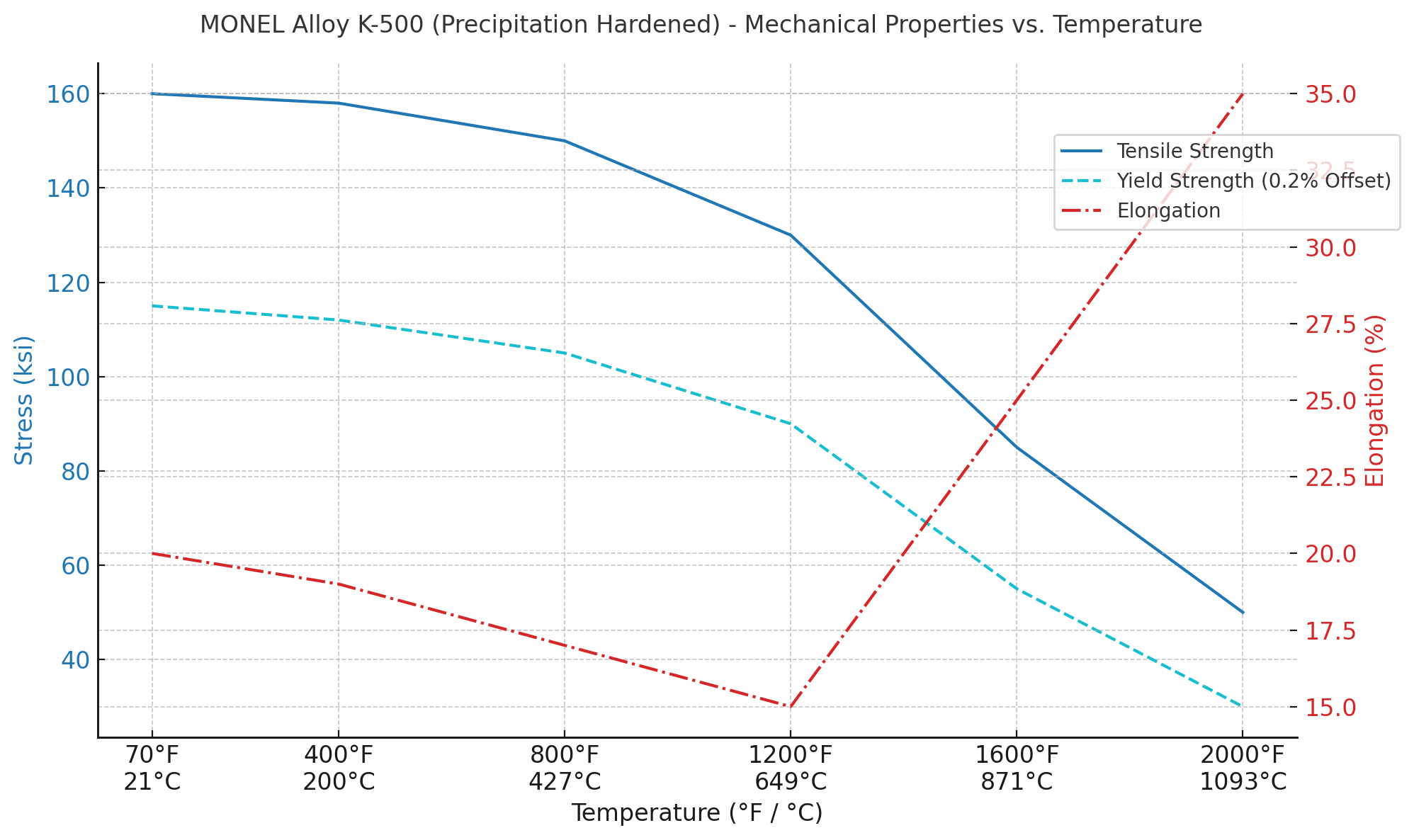

| Monel Alloy K500 Round Bars Mechanical Properties: |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.44 g/cm3 | 1350 °C (2460 °F) | Psi – 160000 , MPa – 1100 | Psi – 115000 , MPa – 790 | 20 % |

Physical Constants and Thermal Properties

| Property | Imperial Units | Metric Units |

|---|---|---|

| Density | 0.305 lb/in³ | 8.44 g/cm³ |

| Melting Range | 2400 – 2460 °F | 1315 – 1350 °C |

| Specific Heat | 0.100 Btu/lb·°F | 419 J/kg·°C |

| Curie Temperature | -150 °F | -100 °C |

| Permeability at 200 Oersted (15.9 kA/m) | 1.002 | – |

| Coefficient of Expansion (70–200°F / 21–93°C) | 7.6 × 10⁻⁶ in/in·°F | 13.7 µm/m·°C |

| Thermal Conductivity | 121 Btu·in/ft²·h·°F | 17.5 W/m·°C |

| Electrical Resistivity | 370 ohm·circ mil/ft | 0.615 µΩ·m |

| Young’s Modulus at RT | 26 × 10³ ksi | — |

Typical Mechanical Properties (Precipitation Hardened)

| Property | Imperial Units | Metric Units |

|---|---|---|

| Tensile Strength | 160 ksi | 1100 MPa |

| Yield Strength (0.2% Offset) | 115 ksi | 790 MPa |

| Elongation | 20% | – |

| Monel K500 Rod PMI Test: |

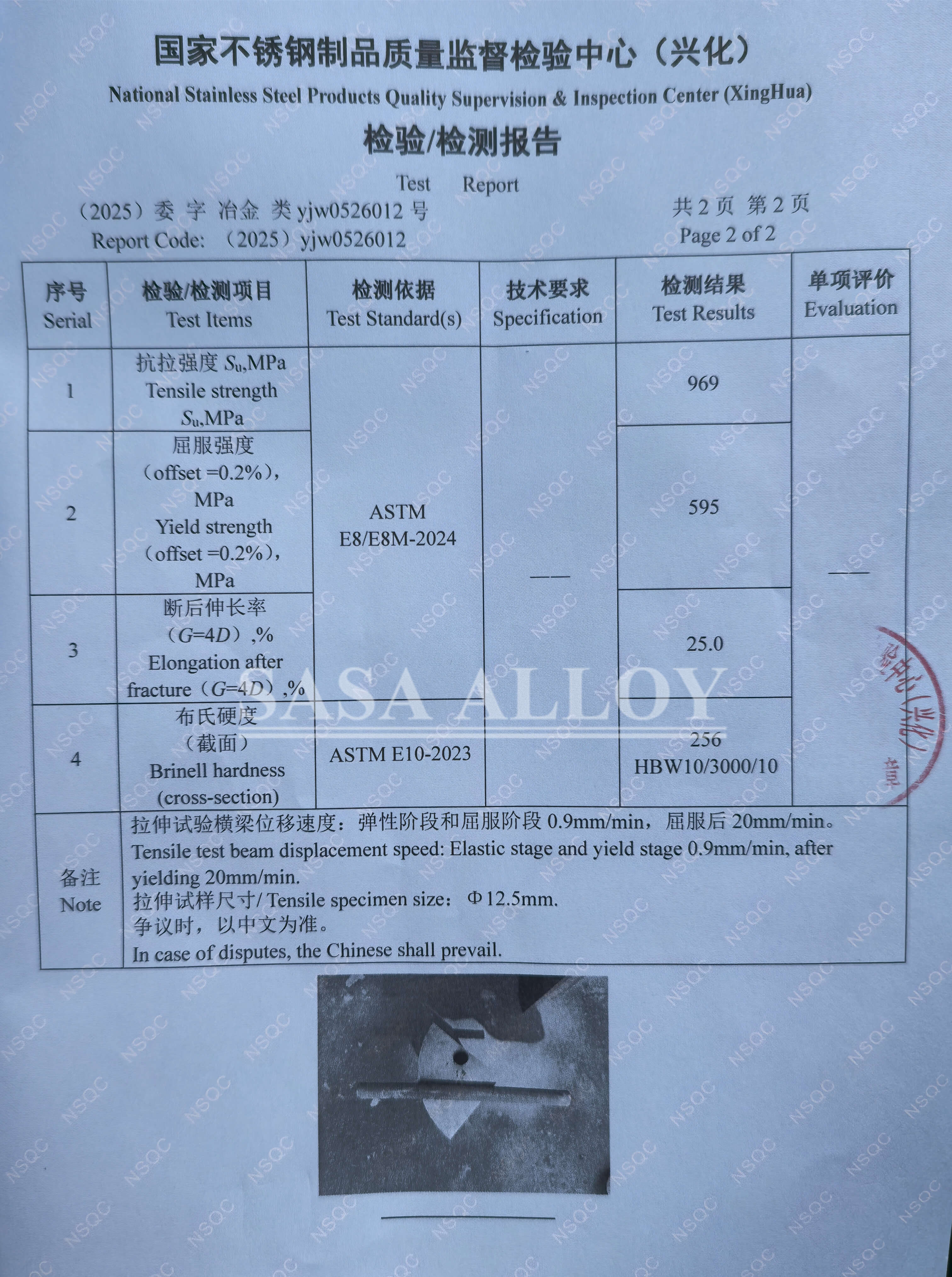

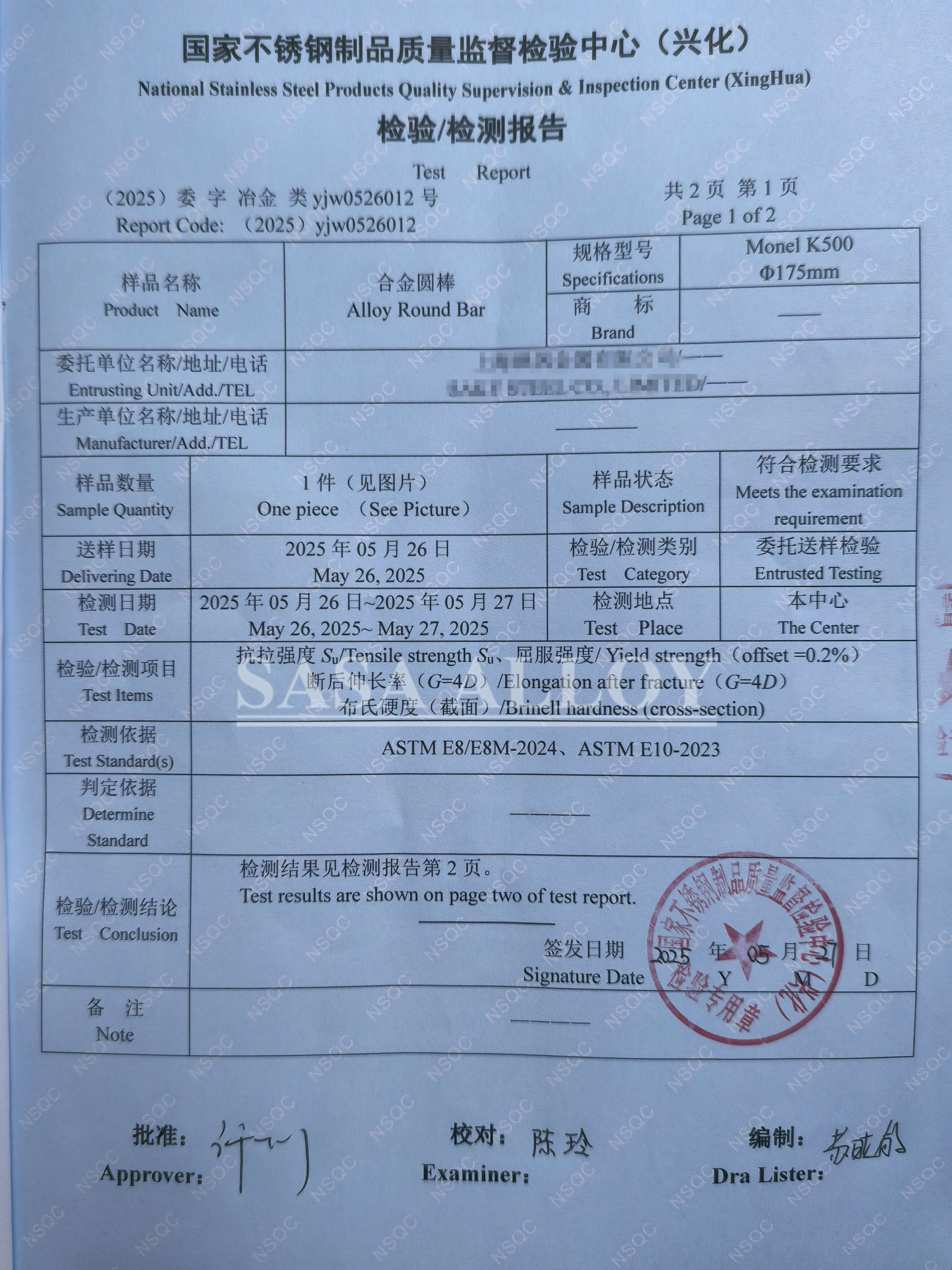

| UNS N05500 Bar Test Report: |

Tested according to ASTM E8/E8M-2024, ASTM E10-2023

| Monel K500 Bar PT Test: |

All tested Monel K500 bars met the acceptance criteria for PT inspection, confirming they are free from surface cracks and other discontinuities. The inspection results ensure the bars meet the high-performance requirements for critical applications such as marine engineering, chemical processing, and oil & gas components.

| Monel K500 Bar UT Test: |

To ensure internal soundness and structural integrity, Monel K500 bars undergo Ultrasonic Testing (UT) in accordance standard or specific customer requirements. This non-destructive method is capable of detecting internal flaws such as inclusions, shrinkage cavities, or cracks.The inspection is performed by certified Level II UT technicians, using calibrated equipment with sensitivity settings aligned to applicable standards. Full-length coverage is ensured, and scan results confirmed the absence of reportable indications. The bars are thus compliant with quality and performance requirements for critical applications.

| Why Choose Us |

At Sasaalloy, we are committed to delivering high-performance Monel K500 bars that meet stringent quality standards. With years of experience in manufacturing and exporting nickel alloys, we offer:

1.Factory-direct pricing

2.ISO 9001:2015 certified production

3.Fast delivery from stock or custom production

4.Mill Test Certificates (MTC) provided

5.Global shipping and responsive customer support

Whether you need standard-sized bars or customized specifications, Sakysteel ensures reliable performance and fast service.

| Monel K500 Rod Packing |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa alloy’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,