INCONEL 718 is a nickel-based superalloy engineered for exceptional strength and corrosion resistance. Its composition features a high nickel content, along with notable additions of chromium and iron, and smaller amounts of elements like molybdenum, niobium, and aluminum. This alloy is valued for its outstanding mechanical performance—offering high tensile and yield strength, superior fatigue resistance, and excellent toughness under stress. It also demonstrates impressive resistance to creep and cracking over long-term service at elevated temperatures.

What is Inconel 718?

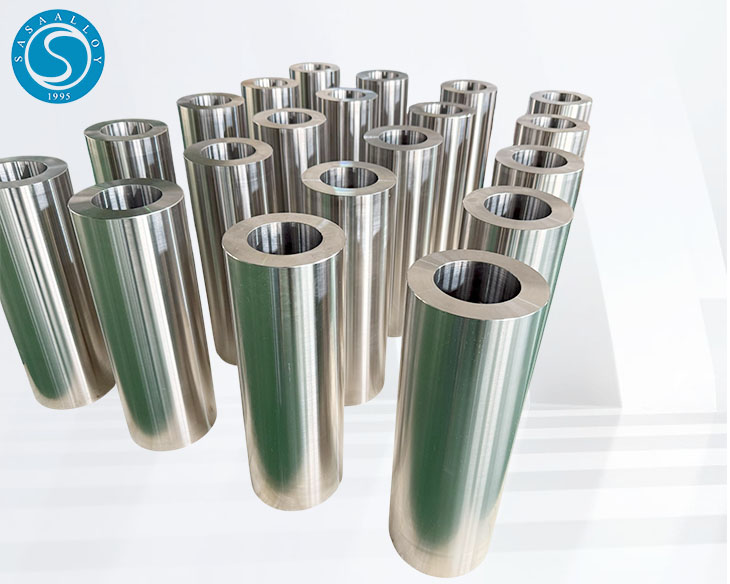

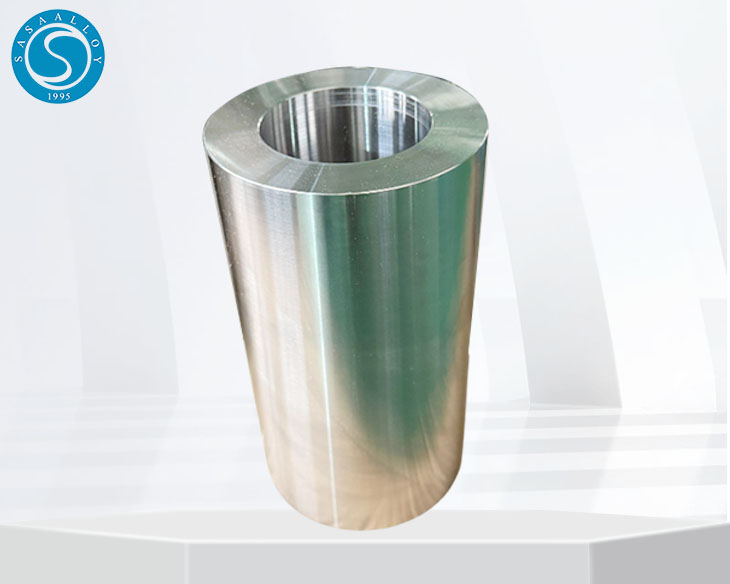

INCONEL 718 (UNS N07718) is a high-strength nickel-based superalloy known for its outstanding performance at elevated temperatures. Composed of nickel, chromium, niobium, molybdenum, and iron, this material delivers excellent corrosion and oxidation resistance. Compliant with ASTM B637, Inconel 718 is widely used in gas turbines, aerospace parts, nuclear reactors, and heat exchangers. Our Inconel 718 forged pipes and nickel alloy seamless tubes are heat-treated and tested to meet strict industry standards.

What is the disadvantage of INCONEL 718?

While Inconel 718 is renowned for its excellent mechanical strength, corrosion resistance, and high-temperature performance, it also comes with a few notable limitations that engineers should consider during material selection.

1. High Cost

Due to its high nickel content and complex processing requirements, Inconel 718 is significantly more expensive than standard stainless steels or lower-grade alloys. This makes it less suitable for cost-sensitive applications.

2. Poor Machinability

Inconel 718 is known for its work-hardening behavior, which makes machining particularly challenging. Cutting tools wear out quickly, leading to increased tool replacement costs and reduced production efficiency.

3. Specialized Weldability Requirements

Although weldable, Inconel 718 requires strict control of welding parameters. Improper welding may lead to cracking or metallurgical defects, potentially compromising structural integrity.

4. High Thermal Expansion

With a relatively high coefficient of thermal expansion, Inconel 718 may experience dimensional changes under temperature fluctuations. This must be taken into account in precision components or assemblies subject to thermal cycling.

Despite these challenges, Inconel 718 remains a top choice for demanding applications in aerospace, energy, and oil & gas sectors, where performance under extreme conditions outweighs its disadvantages.

Advantages of Inconel 718

Inconel 718, a nickel-based superalloy, is widely recognized for its outstanding mechanical and chemical performance in extreme environments. Its key advantages include:

1. High Strength at Elevated Temperatures

Inconel 718 maintains excellent tensile, yield, and fatigue strength even at temperatures up to 700°C (1290°F), making it ideal for high-temperature components in aerospace and power generation.

2. Exceptional Corrosion and Oxidation Resistance

The alloy offers superior resistance to a wide range of corrosive media, including acids, seawater, and high-temperature oxidation, ensuring long-term durability in harsh environments.

3. Outstanding Creep and Stress Rupture Resistance

Its ability to resist deformation under long-term exposure to high stress and heat is critical for components like turbine blades and nuclear reactor parts.

4. Good Weldability

Unlike many other superalloys, Inconel 718 can be welded using conventional techniques with minimal risk of cracking, especially after proper heat treatment.

5. Stability and Toughness

The alloy remains stable under thermal cycling and offers excellent fracture toughness, making it suitable for critical structural applications.

6. Proven Industry Use

Inconel 718 is widely used in aerospace, oil & gas, chemical processing, marine, and nuclear industries, backed by decades of successful performance.

Applications of Inconel 718

Inconel 718 is a high-strength, corrosion-resistant nickel-based superalloy engineered to perform under extreme conditions. Its unique combination of mechanical strength, thermal stability, and resistance to corrosion and oxidation makes it ideal for demanding applications across various industries:

1. Aerospace Industry

Used in jet engine components, turbine blades, exhaust systems, and fasteners due to its ability to withstand high stress and temperatures.

2. Power Generation

Applied in gas and steam turbines, combustors, and heat exchangers where high-temperature strength and oxidation resistance are critical.

3. Oil and Gas Sector

Ideal for downhole tools, valves, fasteners, and high-pressure, high-temperature components exposed to corrosive environments.

4. Nuclear Industry

Utilized in reactor core components, fuel rods, and containment structures due to its radiation resistance and long-term thermal stability.

5. Chemical Processing

Resists aggressive chemicals and oxidation in heat exchangers, reactors, and pressure vessels.

6. Marine and Subsea Applications

Provides excellent resistance to saltwater corrosion, making it suitable for springs, shafts, and pumps in harsh marine environments.

Inconel 718’s broad applicability stems from its ability to maintain structural integrity in extreme heat, pressure, and corrosive conditions, making it a preferred choice for mission-critical nickel alloy components.

Conclusion of Inconel 718

Inconel 718 stands out as a high-performance nickel-based superalloy, offering exceptional mechanical strength, corrosion resistance, and stability at elevated temperatures. Its reliability in extreme environments makes it a preferred material for aerospace, power generation, and oil & gas industries. However, its advantages come with certain trade-offs — including high cost, limited machinability, and specialized welding requirements. Despite these challenges, the superior properties of Inconel 718 often outweigh its disadvantages in critical applications where performance and durability are non-negotiable.

Post time: May-29-2025