Inconel 718 Forged Seamless Pipe

| Table Of Content |

• Specifications of Inconel 718 Forged Seamless Pipe

• UNS N07718 Forged Pipe PMI Test

• CHEMICAL COMPOSITION OF Alloy 718 Forged Pipe

• Nickel Alloy 718 Forged Pipe Mechanical Properties

• Inconel 718 Forged Pipe NDT Test

• Forged Pipe in Inconel 718 Grade Inventory Specifications

• Inconel 718 Forged Pipe PT Test

• 718 Nickel Alloy Forged Pipe Hardness Test

• Inconel 718 Forged Pipe Applications

• UNS N07718 Forged Pipe Test Report

• Dimensional Technical Standard of Inconel Alloy 718 pipe

• 718 Forged Seamless Pipe Packing

• Finishes and Coatings of Inconel Alloy 718 Heat Exchanger Tube

• Inconel 718 Pipe Types Manufacturer In China SASA ALLOY

• Asme Sb163 Uns N07718 Seamless Pipe Price in China

• Available size of Alloy 718 Square Tube

• ASME B36.10M Alloy 718 Pipe Schedule Chart

• Ranging in size from Astm B163 Alloy 718 welded pipe

• Weight table ASME SB163 Alloy 718 Seamless Tube

• Alloy 718 welded pipe testing

• Inconel 718 Pipe Weight Chart

• Nickel Alloy 718 Pipe Documentation

• Pressure Rating of DIN 2.4668 Pipe and Tube

• Frequently Used Inconel 718 Pipe and Tube For Sale

| What is Inconel 718 pipe? |

Inconel 718 Forged Seamless Pipe offers excellent high-temperature strength, corrosion resistance, and weldability, making it ideal for aerospace, oil & gas, and power generation industries. Manufactured to ASTM B983 and AMS 5589/5590 standards, this nickel-based alloy pipe provides superior mechanical properties, including tensile strength of up to 1380 MPa and high creep resistance. With outstanding oxidation resistance up to 980°C (1800°F), it ensures durability in extreme environments. Available in customized sizes and finishes, our Inconel 718 seamless pipes are designed for critical applications.

| Specifications of Inconel 718 Forged Seamless Pipe: |

| ASTM Specification | AMS 5590, AMS 5589 |

|---|---|

| International Specification | WERKSTOFF Nr 2.4668 , UNS N07718 |

| Standard | GB, DTD, ASME, AISI, ASTM, TOCT, JIS, NF, SAE, DIN, AMS, DS, EN |

| Size of Seamless Pipe | Wall thickness.: 0.05- 20 milimeter, 4 - 219 milimeter |

| Size of Welded Pipe | 5.0 to 1219.02 milimeter |

| size of EFW Pipe | 5.0 to 1219.02 milimeter |

| Seamless Tube Size | 3.35 milimeter To 101.6 milimeter OD |

| Welded Tube Size | 6.35 milimeter To 152 milimeter OD |

| Bwg & Swg | 18 Swg., 14 20 Swg., Swg. Swg., 12 16 Swg., 10 Swg. |

| Tubing wall thickness | 0.020" –0.220", (custom wall thicknesses available) |

| Pipe Schedule | SCH20, XS, STD, XXS, SCH60, SCH140, SCH80, SCH80, SCH5, SCH40S, SCH40, SCH120, SCH10S, SCH10, SCH30, SCH160 |

| Length | Standard & Cut length , Single Random, Double Random Pipe |

| Finish | AP (Annealed & Pickled), BA (Bright & Annealed), NO.1, 2B, Polished, MF, HL, NO.4, Mirror finish, BA, 8K etc |

| End | Plain End, Beveled End, Treaded Pipe, Screwed ends |

| Form | Hydraulic, Rectangular, Coiled, Square, Hollow, Round, Straight Pipes/tubes, “U” Shape, Pan Cake Coils, Boiler, LSAWetc. |

| Application | Dairy Pipe, Oil Pipe/tube, Gas Pipe/tube, Fluid Pipe/tube, Boiler Tube, Heat exchanger Tube |

| Type | Seamless /ERW/ EFW / Welded / Fabricated /CDW /DOM/CEW Inconel 718 Pipe |

| Marking | Heat No. (Or as per need.), Thickness, OD, Grade, Standard Length |

| Value Added Service | Expansion and Draw as per needed Length and Size, , Polish (Comilimeterercial and Electro), Machining, Annealed & Pickled Bending Etc. |

| Specialize in | Large Diameter Inconel 718 PipeNickel NW 2200 Capillary Tube & Other Odd Size ASME SB163 Alloy 718 Heat Exchanger & Condenser Tube |

| Suppliers of | Sanyo Special Steel, JapanSumitomo Metals, JapanKobe Special Tube, JapanSeah Steel Corporation, KoreaSchoeller Bleckmann, AustriaTubacex Tubos Inoxidables S.A., SpainNippon Steel Corporation, Japan |

| Test Certificate | Under Third Party InspectionManufacturer Test Certificate |

| Manufacturing Technique | Cold drawn, hot drawn, bright annealed, solid solution, hot extruding |

| Inconel 718 Pipe Types Manufacturer In China SASA ALLOY: |

| CHEMICAL COMPOSITION OF Alloy 718 Forged Pipe: |

| Grade | Ti | Al | C | Fe | Ni | Cr | Mo | Nb |

| 718 | 0.65-1.15 | 0.6-0.8 | 0.08 | bal | 50-55.0 | 17-21 | 2.8-3.3 | 4.75-5.5 |

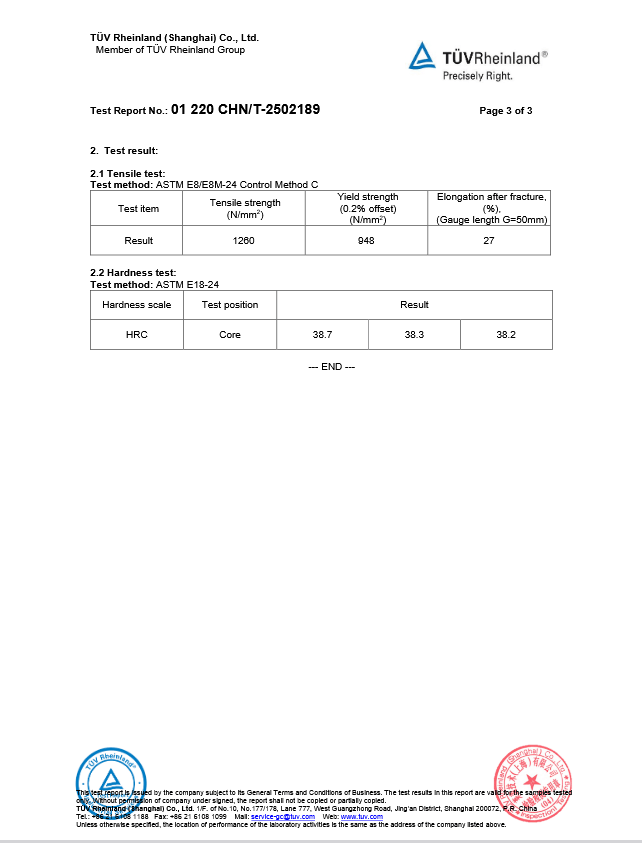

| Nickel Alloy 718 Forged Pipe Mechanical Properties: |

| Tensile Strength | Yield Strength | Elongation |

| MPa – 1240 | MPa – 1030 | 12% |

| Forged Pipe in Inconel 718 Grade Inventory Specifications: |

| Out Diamter(mm) | Wall Thickness(mm) | Stock Length(mm) |

| 12.7 | 1.65 | 6 |

| 25.4 | 2.11 | 6 |

| 50.8 | 3.05 | 6-12 |

| 76.2 | 4.19 | 6-12 |

| 101.6 | 5.74 | 6-10 |

| UNS N07718 Forged Pipe PMI Test: |

Each Inconel 718 forged seamless pipe is subjected to Positive Material Identification (PMI) testing to verify its chemical composition and ensure full material traceability. Using advanced handheld XRF analyzers, we confirm that the alloy content strictly complies with the ASTM B444 or customer-specified standards. This process guarantees that only genuine Inconel 718 material is delivered, ensuring performance in high-temperature, high-stress environments. PMI reports are available upon request.

| Inconel 718 Forged Pipe Applications: |

Inconel 718 Forged Seamless Pipe is extensively used in high-end industrial scenarios, typical applications include:

1.Aerospace: Engine combustion chambers, turbine blades, and exhaust systems

2.Nuclear Industry: Reactor cooling system piping

3.Petrochemical Industry: Offshore drilling platforms, chemical processing pipelines

4.Automotive Industry: High-performance racing exhaust systems

| Inconel 718 Forged Pipe NDT Test: |

Inconel 718 forged seamless pipes undergo rigorous non-destructive testing to ensure internal integrity and surface quality. Ultrasonic testing (UT) is conducted to detect any subsurface cracks, inclusions, or voids, while dye penetrant or magnetic particle testing (as applicable) is used for surface flaw inspection. Testing is performed according to ASTM standards and customer-specific requirements, with complete NDT reports provided upon request.

| Inconel 718 Forged Pipe PT Test: |

PT testing of Inconel 718 alloy tubes can ensure the following:

• The tube surface is free from microcracks, welding defects, and other potential failure risks.

• The safety and reliability of the tubes during service.

• Compliance with quality standards in industries such as aerospace and energy.

| 718 Nickel Alloy Forged Pipe Hardness Test: |

Hardness testing is performed on Inconel 718 seamless pipes to evaluate material strength and heat treatment consistency. Common methods such as Rockwell (HRB/HRC) or Vickers (HV) testing are used to ensure the pipes meet required mechanical property standards for high-performance applications.

| UNS N07718 Forged Pipe Test Report: |

| Inconel 718 Forged Seamless Pipe Why Choose Us |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. Provide SGS TUV report.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

7.Provide one-stop service.

| 718 Forged Seamless Pipe Packing |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa alloy’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

| ASME SB163 Uns N07718 Seamless Pipe Price in China |

| Description | Inconel 718 pipe Price |

|---|---|

| Inconel 718 Seamless Tube/Pipe | US $ 12-18 / kg |

| Inconel 718 Nickel Alloy Pipe | US $ 7.5-40 / kg |

| Inconel 718 Gh4169 N07718 2.4668 Pipe | US $ 100-200 / kg |

| Inconel 718 Nickel Alloy Seamless Pipe | US $ 10-100 / kg |

| Inconel 718 Pipe (UNS N07718, 2.4668, ALLOY 718) | US $ 2400-2600 / Ton |

| Sb168 Inconel 718 Gh4169 Heat Treatment Welded Pipe | US $ 100-200 / kg |

| Inconel 718 Tube Nickel Alloy 718 Welded Pipe | US $ 10000-35000 / Ton |

| Nickel-Chromium Alloy Steel Pipe (N07718 Inconel 718) | US $ 2000-3000 / Ton |

| Nickel Alloy Inconel 718 Seamless Pipe | US $ 10000-30000 / Ton |

| Inconel 718 Seamless Pipe (FM33) | US $ 80-100 / kg |

Please note that the price listed is an indicative estimate for Inconel 718 Pipe in China.

For the most up-to-date pricing of Alloy 718 Tubes in China, feel free to contact us directly.

We also encourage you to compare our rates with other ASME SB163 Inconel 718 Pipe suppliers in China — we strive to offer competitive and reliable pricing.

| Dimensional Technical Standard of Inconel Alloy 718 pipe |

| Nominal Thickness (in) MM |

Pipe Size (in) |

Transverse Areas (in2) MM2 |

Diameter (in) MM |

Volume (ft3/ft) |

Number of Threads per inch of Screw | Weight | Length of Pipe (ft per sq.0 foot of surface) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Internal | External | Steel | Internal | External | (kg/m) | (lb/ft) | Internal Surface (ft) |

External Surface (ft) |

||||

| 0.007 | 1/8 | 0.006 | 0.013 | 0.007 | 0.027 | 0.0405 | 0.00004 | 27 | 0.036 | 0.024 | 14.020 | 9.043 |

| 0.009 | ¼ | 0.010 | 0.023 | 0.013 | 0.036 | 0.0540 | 0.00007 | 18 | 0.063 | 0.042 | 10.049 | 7.007 |

| 0.009 | 3/8 | 0.019 | 0.036 | 0.017 | 0.049 | 0.0675 | 0.00013 | 18 | 0.084 | 0.057 | 7.075 | 5.066 |

| 0.011 | ½ | 0.030 | 0.055 | 0.025 | 0.062 | 0.0840 | 0.00021 | 14 | 1.026 | 0.085 | 6.014 | 4.055 |

| 0.011 | ¾ | 0.053 | 0.087 | 0.033 | 0.082 | 1.0050 | 0.00037 | 14 | 1.068 | 1.013 | 4.064 | 3.064 |

| 0.013 | 1 | 0.086 | 1.036 | 0.049 | 1.005 | 1.0315 | 0.00060 | 11 ½ | 2.050 | 1.068 | 3.064 | 2.090 |

| 0.014 | 1 ¼ | 1.050 | 2.016 | 0.067 | 1.038 | 1.0660 | 0.00104 | 11 ½ | 3.038 | 2.027 | 2.077 | 2.030 |

| 0.015 | 1 ½ | 2.004 | 2.084 | 0.080 | 1.061 | 1.0900 | 0.00141 | 11 ½ | 4.004 | 2.072 | 2.037 | 2.001 |

| 0.015 | 2 | 3.036 | 4.043 | 1.008 | 2.007 | 2.0375 | 0.00233 | 11 ½ | 5.043 | 3.065 | 1.085 | 1.061 |

| 0.020 | 2 ½ | 4.079 | 6.049 | 1.070 | 2.047 | 2.0875 | 0.00333 | 8 | 8.062 | 5.079 | 1.055 | 1.033 |

| 0.022 | 3 | 7.039 | 9.062 | 2.023 | 3.007 | 3.0500 | 0.00513 | 8 | 11.027 | 7.058 | 1.025 | 1.009 |

| 0.023 | 3 ½ | 9.089 | 12.056 | 2.068 | 3.055 | 4.0000 | 0.00687 | 8 | 13.056 | 9.011 | 1.008 | 0.095 |

| 0.024 | 4 | 12.073 | 15.090 | 3.017 | 4.003 | 4.0500 | 0.00884 | 8 | 16.006 | 10.079 | 0.095 | 0.085 |

| 0.026 | 5 | 20.000 | 24.030 | 4.030 | 5.005 | 5.0563 | 0.01389 | 8 | 21.074 | 14.061 | 0.076 | 0.069 |

| 0.028 | 6 | 28.089 | 34.047 | 5.058 | 6.007 | 6.0625 | 0.02006 | 8 | 28.023 | 18.097 | 0.063 | 0.058 |

| 0.032 | 8 | 50.002 | 58.042 | 8.040 | 7.098 | 8.0625 | 0.03552 | 8 | 42.049 | 28.055 | 0.048 | 0.044 |

| 0.037 | 10 | 78.085 | 90.076 | 11.090 | 10.002 | 10.0750 | 0.05476 | 8 | 60.024 | 40.048 | 0.038 | 0.036 |

| 0.041 | 12 | 111.090 | 127.064 | 15.074 | 11.094 | 12.0750 | 0.07763 | 8 | 79.077 | 53.060 | 0.032 | 0.030 |

| 0.044 | 14 | 135.030 | 153.094 | 18.064 | 13.013 | 14.0000 | 0.09354 | 8 | 93.075 | 63.000 | 0.028 | 0.027 |

| 0.050 | 16 | 176.070 | 201.005 | 24.035 | 15.000 | 16.0000 | 1.02230 | 8 | 116.008 | 78.000 | 0.025 | 0.024 |

| 0.056 | 18 | 224.000 | 254.085 | 30.085 | 16.088 | 18.0000 | 1.05550 | 8 | 156.026 | 105.000 | 0.023 | 0.021 |

| 0.059 | 20 | 278.000 | 314.015 | 36.015 | 18.081 | 20.0000 | 1.09260 | 8 | 183.005 | 123.000 | 0.020 | 0.019 |

| 0.069 | 24 | 402.010 | 452.040 | 50.030 | 22.063 | 24.0000 | 2.07930 | 8 | 254.048 | 171.000 | 0.017 | 0.016 |

| Available size of Alloy 718 Square Tube |

| DIMENSIONS | WEIGHT PER | WALL | DIMENSIONS | WEIGHT PER | WALL | |

|---|---|---|---|---|---|---|

| (MM) | METRE (KG) | (MM) | (MM) | METRE (KG) | (MM) | |

| 12.07 x 12.07 | 0.044 | 1.020 | 40 x40 | 1.049 | 1.020 | |

| 12.07 x 12.07 | 0.055 | 1.050 | 40 x40 | 1.085 | 1.050 | |

| 15 x 15 | 0.053 | 1.020 | 40 x40 | 2.045 | 2.000 | |

| 15 x 15 | 0.065 | 1.050 | 40 x40 | 3.075 | 3.000 | |

| 20 x 20 | 0.071 | 1.020 | 50 x50 | 2.032 | 1.050 | |

| 20 x 20 | 0.088 | 1.050 | 50 x50 | 3.008 | 2.000 | |

| 20 x 20 | 1.019 | 2.000 | 50 x50 | 4.065 | 3.000 | |

| 25 x 25 | 0.092 | 1.020 | 60 x60 | 3.071 | 2.000 | |

| 25 x 25 | 1.014 | 1.050 | 60 x60 | 5.049 | 3.000 | |

| 25 x 25 | 1.049 | 2.000 | 70 x70 | 6.053 | 3.000 | |

| 25 x 25 | 2.020 | 3.000 | 80 x80 | 4.098 | 2.000 | |

| 30 x 30 | 1.010 | 1.020 | 80 x80 | 7.053 | 3.000 | |

| 30 x 30 | 1.037 | 1.050 | 100 x 100 | 6.040 | 2.000 | |

| 30 x 30 | 1.084 | 2.000 | 100 x 100 | 9.053 | 3.000 | |

| 30 x 30 | 2.072 | 3.000 | ||||

| ASME B36.10M Alloy 718 Pipe Schedule Chart |

|

3 1/2" IPS( 4.000"O. D.)

|

1/8" IPS(.405"O. D.)

|

|---|---|

|

SCH 40, 10, 160, 80, XXH

|

SCH 40, 80

|

|

4" IPS(4.500"O. D.)

|

1/4" IPS(.540"O. D.)

|

|

SCH 40, 10, 160, 80, XXH

|

SCH 40, 10, 80

|

|

5" IPS( 5.563"O. D.)

|

3/8" IPS(.675"O. D.)

|

|

SCH 40, 10, 160, 80, XXH

|

SCH 40, 10, 80

|

|

6" IPS(6.625"O. D.)

|

1/2" IPS(.840"O. D.)

|

|

SCH 10, 5, 80, 40, 160, 120 XXH

|

SCH 5, 40, 10, 160, 80, XXH

|

|

8 ” IPS(8.625"O. D.)

|

3/4" IPS(1.050"O. D.)

|

|

SCH 10, 5, 80, 40, 160, 120 XXH

|

SCH 40, 10, 160, 80, XXH

|

|

10" IPS(10.750"O. D.)

|

1" IPS:(1.315′O. D.)

|

|

SCH 10, 20, TRUE 80(.500), 40, 80 (.500),

|

SCH 5, 40, 10, 160, 80, XXH

|

|

12" IPS(12.750"O. D.)

|

1-1/4" IPS(1.660"O. D.)

|

|

SCH 10, 20, TRUE40(.406), 40(.375), SCH80(.500)

|

SCH 40, 10, 160, 80, XXH

|

|

14" IPS(14.000"O. D.)

|

1-1/2" IPS(1.900"O. D.)

|

|

SCH10(.188), SCH40(.375)

|

SCH 40, 10, 160, 80, XXH

|

|

16" IPS(16.000"O. D.)

|

2" IPS(2.375"O. D.)

|

|

SCH10(.188), SCH40(.375)

|

SCH 40, 10, 160, 80, XXH

|

|

18" IPS (18.000"O. D.)

|

2 1/2" IPS(2.875"O. D.)

|

|

SCH-40 (.375)

|

SCH 40, 10, 160, 80, XXH

|

|

|

3" IPS( 3.500"O. D.)

|

|

|

SCH 5, 40, 10, 160, 80, XXH

|

| Ranging in size from Astm B163 Alloy 718 welded pipe |

OD = Inconel 718 Pipe outside diameter

WT = Inconel 718 Pipe wall thickness

Great Inconel 718 Pipe suppliers in China offer these Inconel Alloy 718 Tube and Tubing in different size range, from thin wall to thick wall in coils or straight lengths.

We Stock and supply Alloy 718 Nickel Tubings, Buy Asme Sb516 718 Inconel Tubing in your length and save cost.

|

Pipe WT

mm |

ASME SB163 Alloy 718 Pipe OD

mm |

Sch

|

in.0

|

Kg/m

|

|---|---|---|---|---|

|

1.065

|

13.072

|

10S

|

1/4

|

0.050

|

|

2.024

|

13.072

|

40S

|

1/4

|

0.064

|

|

3.002

|

13.072

|

80S

|

1/4

|

0.081

|

|

1.065

|

17.015

|

10S

|

3/8

|

0.064

|

|

2.031

|

17.015

|

40S

|

3/8

|

0.086

|

|

3.020

|

17.015

|

80S

|

3/8

|

1.012

|

|

2.011

|

21.034

|

10S

|

1/2

|

1.002

|

|

2.077

|

21.034

|

40S

|

1/2

|

1.029

|

|

3.073

|

21.034

|

80S

|

1/2

|

1.065

|

|

2.011

|

26.067

|

10S

|

3/4

|

1.030

|

|

2.087

|

26.067

|

40S

|

3/4

|

1.071

|

|

3.091

|

26.067

|

80S

|

3/4

|

2.023

|

|

2.077

|

33.040

|

10S

|

1

|

2.013

|

|

3.038

|

33.040

|

40S

|

1

|

2.054

|

|

4.055

|

33.040

|

80S

|

1

|

3.029

|

|

6.0352)

|

33.040

|

160

|

1

|

4.030

|

|

2.077

|

42.016

|

10S

|

1¼

|

2.073

|

|

3.056

|

42.016

|

40S

|

1¼

|

3.044

|

|

4.085

|

42.016

|

80S

|

1¼

|

4.053

|

|

6.0352)

|

42.016

|

160

|

1¼

|

5.069

|

|

2.077

|

48.026

|

10S

|

1½

|

3.016

|

|

3.068

|

48.026

|

40S

|

1½

|

4.011

|

|

5.008

|

48.026

|

80S

|

1½

|

5.049

|

|

2.077

|

60.033

|

10S

|

2

|

3.099

|

|

3.091

|

60.033

|

40S

|

2

|

5.052

|

|

5.054

|

60.033

|

80S

|

2

|

7.060

|

|

8.0742)

|

60.033

|

160

|

2

|

11.029

|

|

3.005

|

73.003

|

10S

|

2½

|

5.035

|

|

5.016

|

73.003

|

40S

|

2½

|

8.077

|

|

7.001

|

73.003

|

80S

|

2½

|

11.059

|

|

3.005

|

88.090

|

10S

|

3

|

6.056

|

|

5.049

|

88.090

|

40S

|

3

|

11.047

|

|

7.062

|

88.090

|

80S

|

3

|

15.051

|

|

11.0132)

|

88.090

|

160

|

3

|

21.067

|

|

3.005

|

101.060

|

10S

|

3½

|

7.053

|

|

5.074

|

101.060

|

40S

|

3½

|

13.078

|

|

8.008

|

101.060

|

80S

|

3½

|

18.092

|

|

3.005

|

114.030

|

10S

|

4

|

8.050

|

|

6.002

|

114.030

|

40S

|

4

|

16.032

|

|

8.056

|

114.030

|

80S

|

4

|

22.067

|

|

13.0492)

|

114.030

|

160

|

4

|

34.005

|

|

6.055

|

141.030

|

40S

|

5

|

22.010

|

|

9.053

|

141.030

|

80S

|

5

|

31.044

|

|

15.0882)

|

141.030

|

160

|

5

|

49.087

|

|

3.04

|

168.028

|

10S

|

6

|

14.004

|

|

7.011

|

168.028

|

40S

|

6

|

28.069

|

|

10.097

|

168.028

|

80S

|

6

|

43.021

|

|

14.027

|

168.028

|

120

|

6

|

54.075

|

|

18.0262)

|

168.028

|

160

|

6

|

68.059

|

|

8.018

|

219.008

|

40S

|

8

|

43.020

|

|

12.07

|

219.008

|

80S

|

8

|

65.063

|

|

18.023

|

219.008

|

120

|

8

|

91.030

|

|

23.0012)

|

219.008

|

160

|

8

|

112.097

|

| Weight table ASME SB163 Alloy 718 Seamless Tube |

| Avarage Wall inches | Outside Diameter inches | Internal Area (in2) | Inside Diameter inches | D/t Ratio | Tube Cross Sectional Area (in2) |

|---|---|---|---|---|---|

| 0.0020 | 0.0250 | 0.00346 | 0.0210 | 12.050 | 0.00145 |

| 0.0028 | 0.0250 | 0.00296 | 0.0194 | 8.093 | 0.00195 |

| 0.0035 | 0.0250 | 0.00254 | 0.0180 | 7.014 | 0.00236 |

| 0.0049 | 0.0250 | 0.00181 | 0.0152 | 5.010 | 0.00309 |

| 0.0065 | 0.0250 | 0.00113 | 0.0120 | 3.085 | 0.00378 |

| 0.0020 | 0.0375 | 0.00881 | 0.0335 | 18.075 | 0.00223 |

| 0.0028 | 0.0375 | 0.00799 | 0.0319 | 13.039 | 0.00305 |

| 0.0035 | 0.0375 | 0.00731 | 0.0305 | 10.071 | 0.00374 |

| 0.0049 | 0.0375 | 0.00603 | 0.0277 | 7.065 | 0.00502 |

| 0.0065 | 0.0375 | 0.00471 | 0.0245 | 5.077 | 0.00633 |

| 0.0020 | 0.0500 | 0.01662 | 0.0460 | 25.000 | 0.00302 |

| 0.0028 | 0.0500 | 0.01548 | 0.0444 | 17.086 | 0.00415 |

| 0.0035 | 0.0500 | 0.01452 | 0.0430 | 14.029 | 0.00511 |

| 0.0049 | 0.0500 | 0.01213 | 0.0402 | 10.020 | 0.00694 |

| 0.0065 | 0.0500 | 0.01075 | 0.0370 | 7.069 | 0.00888 |

| 0.0083 | 0.0500 | 0.00876 | 0.0334 | 6.002 | 0.01087 |

| 0.0020 | 0.0625 | 0.02688 | 0.0585 | 31.025 | 0.00380 |

| 0.0028 | 0.0625 | 0.02543 | 0.0569 | 22.032 | 0.00525 |

| 0.0035 | 0.0625 | 0.02419 | 0.0555 | 17.086 | 0.00649 |

| 0.0049 | 0.0625 | 0.02181 | 0.0527 | 12.076 | 0.00887 |

| 0.0065 | 0.0625 | 0.01924 | 0.0495 | 9.062 | 0.01144 |

| 0.0083 | 0.0625 | 0.01655 | 0.0459 | 7.053 | 0.01413 |

| 0.0095 | 0.0625 | 0.01486 | 0.0435 | 6.058 | 0.01582 |

| 0.0109 | 0.0625 | 0.01301 | 0.0407 | 5.073 | 0.01767 |

| 0.0028 | 0.0750 | 0.03783 | 0.0694 | 26.079 | 0.00635 |

| 0.0035 | 0.0750 | 0.03632 | 0.0680 | 21.043 | 0.00786 |

| 0.0049 | 0.0750 | 0.03339 | 0.0652 | 15.031 | 0.01079 |

| 0.0065 | 0.0750 | 0.03019 | 0.0620 | 11.054 | 0.01399 |

| 0.0083 | 0.0750 | 0.02679 | 0.0584 | 9.004 | 0.01739 |

| 0.0095 | 0.0750 | 0.02463 | 0.0560 | 7.089 | 0.01955 |

| 0.0109 | 0.0750 | 0.02223 | 0.0532 | 6.088 | 0.02195 |

| 0.0120 | 0.0750 | 0.02043 | 0.0510 | 6.025 | 0.02375 |

| 0.0020 | 0.0875 | 0.05476 | 0.0835 | 43.075 | 0.00537 |

| 0.0028 | 0.0875 | 0.05268 | 0.0819 | 31.025 | 0.00745 |

| 0.0035 | 0.0875 | 0.05090 | 0.0805 | 25.000 | 0.00924 |

| 0.0049 | 0.0875 | 0.04742 | 0.0777 | 17.086 | 0.01272 |

| 0.0065 | 0.0875 | 0.04359 | 0.0745 | 13.046 | 0.01654 |

| 0.0083 | 0.0875 | 0.03948 | 0.0709 | 10.054 | 0.02065 |

| 0.0095 | 0.0875 | 0.03685 | 0.0685 | 9.021 | 0.02328 |

| 0.0109 | 0.0875 | 0.03390 | 0.0657 | 8.003 | 0.02623 |

| 0.0120 | 0.0875 | 0.0316L7 | 0.0635 | 7.029 | 0.02846 |

| 0.0028 | 1.0000 | 0.06999 | 0.0944 | 35.071 | 0.00855 |

| 0.0035 | 1.0000 | 0.06793 | 0.0930 | 28.057 | 0.01061 |

| 0.0049 | 1.0000 | 0.06390 | 0.0902 | 20.041 | 0.01464 |

| 0.0065 | 1.0000 | 0.05945 | 0.0870 | 15.038 | 0.01909 |

| 0.0083 | 1.0000 | 0.05463 | 0.0834 | 12.005 | 0.02391 |

| 0.0095 | 1.0000 | 0.05153 | 0.0810 | 10.053 | 0.02701 |

| 0.0109 | 1.0000 | 0.04803 | 0.0782 | 9.017 | 0.03051 |

| 0.0120 | 1.0000 | 0.04536 | 0.0760 | 8.033 | 0.03318 |

| 0.0134 | 1.0000 | 0.04208 | 0.0732 | 7.046 | 0.03646 |

| 0.0035 | 1.0250 | 1.00936 | 1.0180 | 35.071 | 0.01336 |

| 0.0049 | 1.0250 | 1.00423 | 1.0152 | 25.051 | 0.01849 |

| 0.0065 | 1.0250 | 0.09852 | 1.0120 | 19.023 | 0.02420 |

| 0.0083 | 1.0250 | 0.09229 | 1.0084 | 15.006 | 0.0316L3 |

| 0.0095 | 1.0250 | 0.08825 | 1.0060 | 13.016 | 0.03447 |

| 0.0109 | 1.0250 | 0.08365 | 1.0032 | 11.047 | 0.03907 |

| 0.0120 | 1.0250 | 0.08012 | 1.0010 | 10.042 | 0.04260 |

| 0.0134 | 1.0250 | 0.07574 | 0.0982 | 9.033 | 0.04698 |

| 0.0035 | 1.0500 | 1.06061 | 1.0430 | 42.086 | 0.01611 |

| 0.0049 | 1.0500 | 1.05438 | 1.0402 | 30.061 | 0.02234 |

| 0.0065 | 1.0500 | 1.04741 | 1.0370 | 23.008 | 0.02930 |

| 0.0083 | 1.0500 | 1.03977 | 1.0334 | 18.007 | 0.03695 |

| 0.0095 | 1.0500 | 1.03478 | 1.0310 | 15.079 | 0.04193 |

| 0.0109 | 1.0500 | 1.02908 | 1.0282 | 13.076 | 0.04763 |

| 0.0120 | 1.0500 | 1.02469 | 1.0260 | 12.050 | 0.05202 |

| 0.0134 | 1.0500 | 1.01921 | 1.0232 | 11.019 | 0.05750 |

| 0.0148 | 1.0500 | 1.01385 | 1.0204 | 10.014 | 0.06286 |

| 0.0035 | 1.0750 | 2.02167 | 1.0680 | 50.000 | 0.01886 |

| 0.0049 | 1.0750 | 2.08413 | 1.0902 | 40.082 | 0.03003 |

| 0.0065 | 1.0750 | 2.00612 | 1.0620 | 26.092 | 0.03441 |

| 0.0083 | 1.0750 | 1.09706 | 1.0584 | 21.008 | 0.04347 |

| 0.0095 | 1.0750 | 1.09113 | 1.0560 | 18.042 | 0.04939 |

| 0.0109 | 1.0750 | 1.08433 | 1.0532 | 16.006 | 0.05619 |

| 0.0120 | 1.0750 | 1.07908 | 1.0510 | 14.058 | 0.06145 |

| 0.0134 | 1.0750 | 1.07250 | 1.0482 | 13.006 | 0.06803 |

| 0.0148 | 1.0750 | 1.06604 | 1.0454 | 11.082 | 0.07449 |

| 0.0165 | 1.0750 | 1.05837 | 1.0420 | 10.061 | 0.08216 |

| 0.0035 | 2.0000 | 2.09255 | 1.0930 | 57.014 | 0.02161 |

| 0.0049 | 2.0000 | 2.08413 | 1.0902 | 40.082 | 0.03003 |

| 0.0065 | 2.0000 | 2.07465 | 1.0870 | 30.077 | 0.03951 |

| 0.0083 | 2.0000 | 2.06417 | 1.0834 | 24.010 | 0.04999 |

| 0.0095 | 2.0000 | 2.05730 | 1.0810 | 21.005 | 0.05685 |

| 0.0109 | 2.0000 | 2.04941 | 1.0782 | 18.035 | 0.06475 |

| 0.0120 | 2.0000 | 2.04328 | 1.0760 | 16.067 | 0.07087 |

| 0.0134 | 2.0000 | 2.03561 | 1.0732 | 14.093 | 0.07855 |

| 0.0148 | 2.0000 | 2.02805 | 1.0704 | 13.051 | 0.08611 |

| 0.0165 | 2.0000 | 2.01904 | 1.0670 | 12.012 | 0.09512 |

| Alloy 718 welded pipe testing |

• Flaring Test

• Flattening Test

• Micro and MacroTest

• Intergranular Corrosion (IGC) Test

• Pitting Resistance Test

• Chemical Analysis – Spectro Analysis

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Positive Material Identification – PMI Testing

| Inconel 718 Pipe Weight Chart |

|

NPS

|

Wall Thickness

|

Outside Diameter

|

Weight

|

Weight

|

|||

|

inch

|

milimeter

|

inch

|

milimeter

|

kg/Mtr

|

Schedule

|

Lb/ft

|

|

|

1/2″

|

0.0109

|

2.0769

|

0.0840

|

21

|

1.0268

|

40 STD

|

0.0851

|

|

0.0147

|

3.0734

|

1.0621

|

80 STD

|

1.0088

|

|||

|

3/4″

|

0.0113

|

2.0870

|

1.0050

|

27

|

1.0684

|

40 STD

|

1.0131

|

|

0.0154

|

3.0912

|

2.0195

|

80 STD

|

1.0474

|

|||

|

1″

|

0.0133

|

3.0378

|

1.0315

|

33

|

2.0501

|

40 STD

|

1.0679

|

|

0.0179

|

4.0547

|

3.0325

|

80 STD

|

2.0172

|

|||

|

1 1/4″

|

0.0140

|

3.0556

|

1.0660

|

42

|

3.0385

|

40 STD

|

2.0273

|

|

0.0191

|

4.0851

|

4.0464

|

80 STD

|

2.0997

|

|||

|

1 1/2″

|

0.0145

|

3.0683

|

1.0900

|

48

|

4.0048

|

40 STD

|

2.0718

|

|

0.0200

|

5.0080

|

5.0409

|

80 STD

|

3.0361

|

|||

|

2″

|

0.0154

|

3.0912

|

2.0375

|

60

|

5.0441

|

40 STD

|

3.0653

|

|

0.0218

|

5.0537

|

7.0480

|

80 STD

|

5.0022

|

|||

|

2 1/2″

|

0.0203

|

5.0516

|

2.0875

|

73

|

8.0629

|

40 STD

|

5.0793

|

|

0.0276

|

7.0010

|

11.0411

|

80 STD

|

7.0661

|

|||

|

3″

|

0.0216

|

5.0486

|

3.0500

|

89

|

11.0284

|

40 STD

|

7.0576

|

|

0.0300

|

7.0620

|

15.0272

|

80 STD

|

10.0253

|

|||

|

4″

|

0.0237

|

6.0020

|

4.0500

|

114

|

16.0073

|

10.0790

|

|

|

0.0337

|

8.0560

|

22.0318

|

14.0983

|

||||

|

6″

|

0.0188

|

4.0775

|

6.0625

|

168

|

19.0252

|

12.0924

|

|

|

0.0203

|

5.0516

|

20.0739

|

13.0923

|

||||

|

0.0219

|

5.0563

|

22.0318

|

14.0983

|

||||

|

0.0250

|

6.0350

|

25.0354

|

17.0021

|

||||

|

0.0280

|

7.0112

|

58.0263

|

40 STD

|

18.0974

|

|||

|

0.0312

|

7.0925

|

31.0334

|

21.0036

|

||||

|

0.0375

|

9.0525

|

37.0285

|

25.0031

|

||||

|

0.0432

|

10.0973

|

42.0561

|

80 XHY

|

28.0573

|

|||

|

0.0500

|

12.0700

|

48.0719

|

32.0708

|

||||

|

8″

|

0.0188

|

4.0775

|

8.0625

|

219

|

25.0233

|

16.0940

|

|

|

0.0203

|

5.0156

|

27.0198

|

18.0259

|

||||

|

0.0219

|

5.0563

|

29.0286

|

19.0661

|

||||

|

0.0250

|

6.0350

|

33.0308

|

20

|

22.0361

|

|||

|

0.0277

|

7.0036

|

36.0786

|

30

|

24.0696

|

|||

|

0.0322

|

8.0179

|

42.0352

|

40

|

28.0554

|

|||

|

0.0375

|

9.0525

|

49.0216

|

33.0041

|

||||

|

0.0406

|

10.0312

|

53.0085

|

60

|

35.0638

|

|||

|

0.0500

|

12.0700

|

64.0627

|

80 XHY

|

43.0388

|

|||

|

10″

|

0.0188

|

4.0775

|

10.0750

|

273

|

31.0588

|

21.0207

|

|

|

0.0219

|

5.0563

|

36.0689

|

24.0631

|

||||

|

0.0250

|

6.0350

|

41.0759

|

20

|

28.0035

|

|||

|

0.0307

|

7.0798

|

51.0002

|

30

|

34.0240

|

|||

|

0.0344

|

8.0738

|

56.0946

|

38.0231

|

||||

|

0.0365

|

9.0271

|

63.0301

|

40 STD

|

40.0483

|

|||

|

0.0438

|

11.0125

|

71.0852

|

48.0238

|

||||

|

0.0500

|

12.0700

|

81.0530

|

60 XHY

|

54.0735

|

|||

|

0.0594

|

15.0088

|

95.0969

|

80

|

64.0429

|

|||

|

12″

|

0.0188

|

4.0775

|

12.0750

|

324

|

37.0570

|

25.0222

|

|

|

0.0219

|

5.0563

|

43.0657

|

29.0309

|

||||

|

0.0250

|

6.0350

|

49.0713

|

33.0375

|

||||

|

0.0281

|

7.0137

|

55.0739

|

37.0420

|

||||

|

0.0312

|

7.0925

|

61.0735

|

41.0445

|

||||

|

0.0375

|

9.0525

|

73.0824

|

49.0562

|

||||

|

0.0406

|

10.0312

|

79.0727

|

53.0525

|

||||

|

0.0500

|

12.0700

|

97.0438

|

65.0415

|

||||

|

0.0562

|

14.0275

|

108.0966

|

73.0154

|

||||

|

14″

|

0.0188

|

4.0775

|

14.0000

|

356

|

41.0308

|

27.0732

|

|

|

0.0219

|

5.0563

|

48.0012

|

32.0233

|

||||

|

0.0250

|

6.0350

|

54.0685

|

20

|

36.0713

|

|||

|

0.0281

|

7.0137

|

61.0327

|

41.0172

|

||||

|

0.0312

|

7.0925

|

67.0939

|

45.0611

|

||||

|

0.0375

|

9.0525

|

81.0281

|

STD

|

54.0568

|

|||

|

0.0438

|

11.0125

|

94.0498

|

40

|

63.0441

|

|||

|

0.0500

|

12.0700

|

107.0381

|

XHY

|

72.0090

|

|||

| 0.0625 |

15.0875

|

132.0983

|

89.0278

|

||||

|

16”

|

0.0188

|

4.0775

|

16.0000

|

406

|

47.0290

|

21.0748

|

|

|

0.0219

|

5.0563

|

54.0980

|

36.0910

|

||||

|

0.0250

|

6.0350

|

62.0639

|

10

|

42.0053

|

|||

|

0.0281

|

7.0137

|

70.0268

|

47.0174

|

||||

|

0.0312

|

7.0925

|

77.0866

|

20

|

52.0275

|

|||

|

0.0344

|

8.0738

|

85.0677

|

57.0519

|

||||

|

0.0375

|

9.0525

|

93.0213

|

30 STD |

62.0578

|

|||

|

0.0438

|

11.0125

|

108.0433

|

72.0797

|

||||

|

0.0500

|

12.0700

|

123.0289

|

40 XHY |

82.0770

|

|||

|

18″

|

0.0219

|

5.0563

|

18.0000

|

457

|

61.0948

|

41.0588

|

|

|

0.0250

|

6.0350

|

70.0593

|

47.0393

|

||||

|

0.0281

|

7.0137

|

79.0208

|

53.0176

|

||||

|

0.0312

|

7.0925

|

87.0792

|

20

|

58.0939

|

|||

|

0.0375

|

9.0525

|

105.0144

|

STD

|

70.0588

|

|||

|

0.0438

|

11.0125

|

122.0369

|

30

|

82.0152

|

|||

|

0.0500

|

12.0700

|

139.0198

|

XHY

|

93.0450

|

|||

|

0.0562

|

14.0275

|

155.0904

|

40

|

104.0666

|

|||

|

0.0625

|

15.0875

|

172.0754

|

115.0978

|

||||

|

20″

|

0.0250

|

6.0350

|

20.0000

|

508

|

78.0547

|

52.0733

|

|

|

0.0282

|

7.0163

|

88.0458

|

59.0386

|

||||

|

0.0312

|

7.0925

|

97.0719

|

65.0604

|

||||

|

0.0375

|

9.0525

|

117.0075

|

20 STD

|

78.0598

|

|||

|

0.0438

|

11.0125

|

136.0305

|

91.0508

|

||||

|

0.0500

|

12.0700

|

155.0106

|

30 XHY

|

104.0130

|

|||

|

0.0594

|

15.0088

|

183.0378

|

40

|

123.0110

|

|||

|

0.0625

|

15.0875

|

192.0640

|

129.0328

|

||||

|

0.0688

|

17.0475

|

211.0368

|

141.0901

|

||||

|

24″

|

0.0250

|

6.0350

|

24.0000

|

610

|

94.0456

|

63.0413

|

|

|

0.0281

|

7.0137

|

106.0029

|

71.0183

|

||||

|

0.0312

|

7.0925

|

117.0573

|

18.0932

|

||||

|

0.0375

|

9.0525

|

140.0938

|

20 STD

|

64.0618

|

|||

|

0.0438

|

11.0125

|

164.0176

|

110.0219

|

||||

|

0.0500

|

12.0700

|

186.0923

|

XHY

|

125.0490

|

|||

|

0.0625

|

15.0875

|

232.0410

|

156.0028

|

||||

|

0.0688

|

17.0475

|

255.0148

|

40

|

171.0293

|

|||

|

0.0750

|

19.0050

|

277.0401

|

186.0233

|

||||

|

30″

|

0.0250

|

6.0350

|

30.0000

|

762

|

118.0318

|

79.0433

|

|

|

0.0281

|

7.0137

|

132.0851

|

89.0189

|

||||

|

0.0312

|

7.0925

|

147.0353

|

10

|

98.0925

|

|||

|

0.0375

|

9.0525

|

176.0731

|

STD

|

118.0648

|

|||

|

0.0438

|

11.0125

|

205.0983

|

138.0286

|

||||

|

0.0500

|

12.0700

|

234.0647

|

20 XHY

|

157.0530

|

|||

|

0.0625

|

15.0875

|

292.0066

|

30

|

196.0078

|

|||

|

0.0688

|

17.0475

|

320.0817

|

215.0380

|

||||

|

0.0750

|

19.0050

|

348.0988

|

234.0293

|

||||

|

36″

|

0.0250

|

6.0350

|

36.0000

|

914

|

142.0180

|

95.0453

|

|

|

0.0281

|

7.0137

|

159.0672

|

107.0196

|

||||

|

0.0312

|

7.0925

|

177.0133

|

10

|

118.0918

|

|||

|

0.0375

|

9.0525

|

215.0525

|

STD

|

142.0678

|

|||

|

0.0438

|

11.0125

|

247.0790

|

166.0353

|

||||

|

0.0500

|

12.0700

|

282.0372

|

20 XHY

|

198.0570

|

|||

|

0.0625

|

15.0875

|

351.0723

|

236.0128

|

||||

|

0.0688 |

17.0475

|

386.0487

|

259.0467

|

||||

|

0.0750 |

19.0050

|

420.0576

|

282.0353

|

||||

|

42″

|

0.0312

|

7.0925

|

42.0000

|

1067

|

206.0914

|

138.0911

|

|

|

0.0375

|

9.0525

|

248.0319

|

STD

|

166.0708

|

|||

|

0.0500

|

12.0700

|

33.0097

|

XHY

|

221.0610

|

|||

|

0.0750

|

19.0050

|

492.0163

|

330.0413

|

||||

|

48″

|

0.0375

|

9.0525

|

48.0000

|

1219

|

284.0112

|

STD

|

190.0738

|

|

0.0438

|

11.0125

|

331.0404

|

222.0487

|

||||

|

0.0500

|

12.0700

|

377.0822

|

XHY

|

253.0650

|

|||

|

0.0750

|

19.0050

|

563.0750

|

378.0473

|

||||

|

0.0875

|

22.0225

|

655.0969

|

440.0383

|

||||

| Nickel Alloy 718 Pipe Documentation |

• NABL approved Laboratory Test Reports

• Material Traceability Records

• Form A for the purposes of the Generalized System of Preferences (GSP)

• Raw Material Test Reports

• Commercial Invoice which includes HS Code

• Guarantee Letter

• Quality Assurance Plan (QAP)

• Test Certificates certifying NACE MR0103, NACE MR0175

• Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

• Heat Treatment Charts

• EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

• Fumigation Certificates

| Pressure Rating of DIN 2.4668 Pipe and Tube |

| Inconel 718 Pipe O.D. (in.) |

Wall Thickness of Inconel 718 Pipe (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0.028 | 0.035 | 0.083 | 0.049 | 0.065 | 0.095 | 0.109 | 0.120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 4000 | 2200 | 3000 | 4600 | ||||

| 1 | 2900 | 2200 | 3400 | 3900 | 4300 | |||

| Frequently Used Inconel 718 Pipe and Tube For Sale |

|

Inconel 718 Exhaust Pipes

|

Inconel 718 718 Inconel Round Pipes

|

|

Schedule 40 Inconel 718 Pipes

|

UNS N07718 EFW Pipes

|

|

Inconel 718 Pipes material

|

Inconel 718 Hexagonal Pipes

|

|

ASME SB163 Inconel 718 Capillary Pipes

|

Astm B163 2.4668 Inconel 718 Custom Pipes

|

|

Small diameter Inconel 718 Pipes

|

Inconel 718 Rectangular Pipes

|

|

High pressure 718 Inconel Pipes

|

Capillary ASME SB163 Inconel 718 Thin Pipes

|

|

DIN NR. 2.4668 Clad Pipes

|

Inconel 718 Bush Hex Pipes

|

|

Inconel 718 Thin Wall Pipes

|

718 alloy Square Pipes

|

|

Inconel 718 Rectangular Tube

|

Inconel 718 elliptical and Oval Tube

|

|

Inconel 718 SCH 80 Tube

|

2.4668 Inconel 718 Alloy SCH 40 Tube

|

|

Inconel 718 Bellows Tubes

|

Inconel 718 High-strength capillary tubing

|

|

Inconel 718 Transmission Tubes

|

ASME SB163 2.4668 Inconel 718 precision Tubes

|

|

Astm B163 Inconel 718 Electropolished Tube

|

Inconel 718 Instrumentation Tube

|

|

Inconel 718 Electropolished Tube

|

Inconel 718 Seamless Hollow Tube

|

|

Astm B516 2.4668 Inconel 718 Oil & Gas Tubing

|

Inconel 718 Condenser Tube

|

|

Inconel 718 SCH 80 Tube

|

Inconel 718 SCH 40 Tube

|

|

Inconel 718 Aero engine Tubes

|

Inconel 718 cold drawn seamless Tubes

|

|

Inconel 718 Furnace Tubes

|

Inconel 718 Gas Tubing

|

|

Inconel 718 Cold drawn seamless tubing (CDS)

|

Inconel 718 Hot finished seamless tubing (HFS)

|

|

Inconel 718 High Pressure Tubes

|

2.4668 Inconel 718 Alloy Precision Tubing

|

|

ASME SB163 UNS N07718 Capillary Tubing

|

Inconel 718 Bourdon Tubes

|

|

Inconel 718 Finned Tubes

|

Inconel 718 Drawn over mandrel (DOM)

|

|

Inconel 718 Furnace Tubes

|

Inconel 718 Aerospace Engine Tubes

|

|

Inconel 718 seamless straight tubing

|

Inconel 718 seamless coil tubing

|

| Outer Diameter (OD) of Inconel 718 Tube |

| Types | Out diameter | Length | Wall thickness |

|---|---|---|---|

| NB Sizes (available) | 1/8” ~ 8” | Upto 6 Meters | SCH 40 /SCH 10 /SCH 160/ SCH 5 / SCH 80 |

| Inconel 718 Seamless tube (as per need) | 5.00 milimeter ~ 203.02 milimeter | as per need | |

| Inconel 718 Welded tube (available + as per need) | 5.00 milimeter ~ 1219.02 milimeter | 1.00 ~ 15.00 milimeter |

| Finishes and Coatings of Inconel Alloy 718 Heat Exchanger Tube |

• Novolac Epoxy

• High Functionality Epoxy - Curran Coating

• liquid epoxy coatings

• Thin Film Engineered Polymer Coatings

• HVAC Chillers and Heat Exchanger Coatings

• Sakaphen- Shell and tube heat exchanger lining

• Surface Condenser Tube Sheets

• IGS high velocity thermal spray (HVTS) coating solutions

• Phenol Epoxy

• Curran 1000 T Hybrid Epoxy

| 718 Inconel Welded Tube Tolerances |

| WALL THICKNESS INCHES | OD +/- INCHES | OD INCHES |

|---|---|---|

| 0.0025 - 0.0065 | 0.0005 | 1/2" - 1" incl0.0 |

| Over 0.0065 - 0.0134 | 0.0010 | |

| 0.0025 - 0.0065 | 0.0008 | 1 - 1-1/2" incl0.0 |

| Over 0.0065 - 0.0134 | 0.0010 | |

| 0.0025 - 0.0049 | 0.0010 | 1-1/2" - 2" incl0.0 |

| Over 0.0049 - 0.0083 | 0.0011 | |

| Over 0.0083 - 0.0148 | 0.0012 | |

| 0.0032 - 0.0065 | 0.0012 | 2" - 2-1/2" incl0.0 |

| Over 0.0065 - 0.0109 | 0.0013 | |

| Over 0.0109 - 0.0165 | 0.0014 | |

| 0.0032 - 0.0165 | 0.0014 | 2-1/2" - 3-1/2" incl0.0 |

| Over 0.0165 - 0.0220 | 0.0020 | |

| 0.0083 - 0.0165 | 0.0020 | 3-1/2" - 5" incl0.0 |

| Over 0.0165 - 0.0220 | 0.0025 |