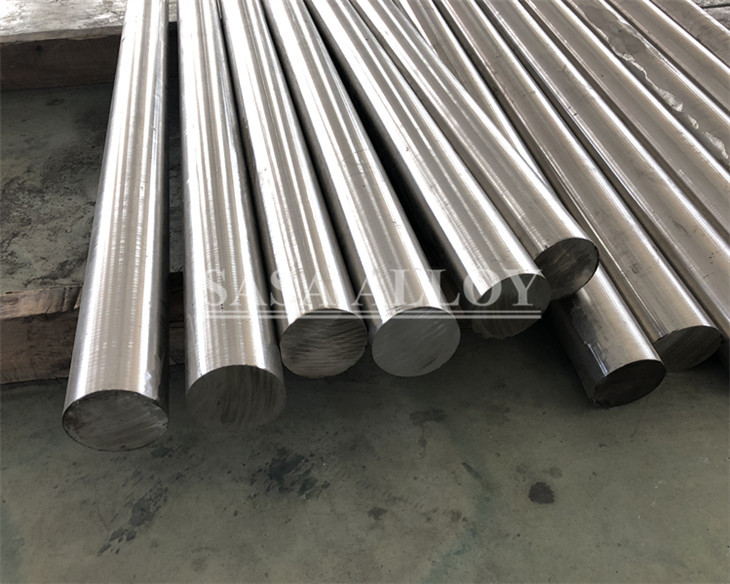

SASA ALLOY, a global leader in specialty alloys, has successfully delivered high-performance K500 nickel-copper alloy bars for a deepwater subsea valve project located in the Gulf of Mexico. This high-profile project, commissioned by a major offshore engineering contractor, involves the development of high-pressure subsea valves for oil extraction at depths exceeding 1,500 meters.

Engineers selected Monel K500 round bars as the primary material for valve stems, shafts, and fastening components due to the alloy’s proven performance in high-stress marine environments. These bars were forged, aged, and precision-machined by SASA ALLOY in accordance with ASTM B865 and NACE MR0175 standards, ensuring superior mechanical properties and long-term corrosion resistance in chloride-rich seawater.

Why K500 Is Ideal for Subsea Valve Systems

Monel K500 is a precipitation-hardened nickel-copper alloy that offers a unique combination of high strength, toughness, and excellent corrosion resistance. It is particularly well-suited for subsea applications where components are continuously exposed to saltwater, pressure cycling, and extreme mechanical stress.

Key Technical Advantages:

• Corrosion Resistance: Unmatched resistance to seawater, brine, and high-pressure acidic environments.

• High Strength: Nearly double the tensile and yield strength of standard Monel 400 due to precipitation hardening with Ti and Al.

• Fatigue Resistance: Withstands cyclic stresses caused by valve opening/closing in subsea operations.

• Non-Magnetic Properties: Ideal for components near instrumentation or magnetic sensors.

• Dimensional Stability: Maintains shape and mechanical integrity under fluctuating temperatures and loads.

These characteristics made Monel K500 bars the perfect solution for this application, where long service life and zero failure tolerance are required.

Project-Specific Requirements

The Gulf of Mexico’s deepwater environment presents extreme technical challenges: high hydrostatic pressure, low ambient temperatures, and the risk of hydrogen sulfide (H₂S) corrosion. Components such as valve shafts and actuator rods must endure thousands of open/close cycles without galling, deformation, or leakage.

SASA ALLOY worked closely with the customer’s engineering team to provide full material traceability, 100% ultrasonic testing, intergranular corrosion testing, and third-party inspection for every batch of bars supplied.

Customizations included:

1.Bar sizes from Ø30 mm to Ø120 mm, forged and aged

2.Ultrasonic Testing (UT) Level 2 as per EN10228

3.Surface finish Ra ≤ 1.6 μm for valve stem contact zones

4.Mechanical properties: ≥ 860 MPa yield strength, ≥ 20% elongation

SASA ALLOY’s Commitment to Alloy Reliability

With years of experience supplying high-performance nickel alloys, SASA ALLOY maintains tight process control over melting, forging, heat treatment, and inspection. The company’s production of Monel K500 bars supports industries including oil & gas, chemical processing, marine engineering, aerospace, and defense.

Through a global logistics network and ISO 9001:2015 certified manufacturing systems, SASA ALLOY continues to deliver high-spec materials to critical infrastructure projects across the globe.

Industry Outlook: K500 Alloy in Offshore Development

As the global demand for offshore drilling and deepwater extraction grows, reliable and corrosion-resistant materials like K500 will remain essential. With growing interest in carbon capture, subsea hydrogen transport, and ultra-deepwater exploration, Monel K500 is expected to see further expansion in use for springs, pump shafts, seals, and valve components.

Conclusion

This Gulf of Mexico subsea valve project demonstrates how Monel K500’s material superiority can directly support mission-critical offshore engineering. Clients who choose SASA ALLOY benefit from expert material consultation, fast global delivery, and the confidence of proven performance in the harshest environments.

Post time: Jun-18-2025