Inconel 625 Wire

Inconel 625 Wire (UNS N06625), a nickel-chromium-molybdenum-niobium alloy known for its exceptional strength, corrosion resistance, and high temperature performance. Designed for demanding environments, this wire is ideal for aerospace, marine, chemical processing, and nuclear applications.Our Inconel 625 wire is available in a variety of diameters (0.1 mm to 5.0 mm), surface finishes (bright, oxidized, or pickled), and conditions (soft annealed or cold drawn). Custom packaging and spool sizes are available upon request.

| Specifications of Inconel 625 Wire: |

| Specifications | ASTM B446 |

|---|---|

| Dimensions | ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360 |

| Length | 100 mm TO 6000 mm, customizable |

| Diameter | 10 mm To 100 mm or as per client requirement |

| Density | 8.4g/cm3 |

|

580-750 |

|

as standard |

|

30 |

| Surface | Polished bright, Smooth |

| Technique | Cold Rolled, hot rolled |

| Condition | M, Y, 1/2Hard |

| Tempers | Tempers range from dead soft annealed to ultra spring temper |

| Alloy 625 Wire Equivalent Grades: |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

| CHEMICAL COMPOSITION OF UNS N06625 Wire: |

| Grade | C | Mn | Si | P | S | Cr | Fe | Ni | Al | Ti |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 | 0.15 min | 20.0–23.0 | 5.0 max | 58.0 min | 0.40 | 0.40 |

| Inconel 625 cold drawn wire Mechanical Properties: |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

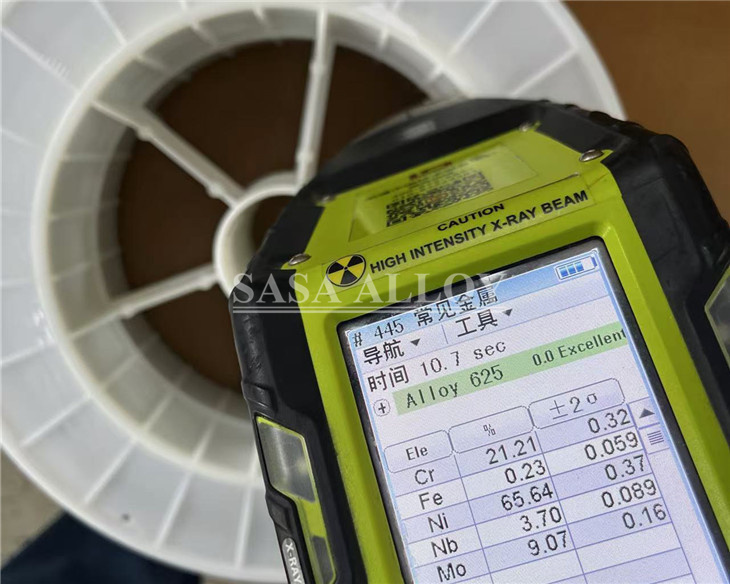

| Nickel Alloy 625 Wire PMI Test: |

Each Inconel 625 wire is subjected to Positive Material Identification (PMI) testing to verify its chemical composition and ensure full material traceability. Using advanced handheld XRF analyzers, we confirm that the alloy content strictly complies with the ASTM B446 or customer-specified standards. This process guarantees that only genuine Inconel 625 material is delivered, ensuring performance in high-temperature, high-stress environments. PMI reports are available upon request.

| Applications of NiCrMoNb 625 Wire: |

-

1.Aerospace: Engine components, heat shields, high-temp springs

-

2.Marine: Anti-corrosion fasteners, cable braiding, seawater-resistant parts

-

3.Oil & Gas: Downhole springs, sealing wires, NACE-compliant uses

-

4.Nuclear & Power: Heat exchanger wire, reactor components

-

5.Chemical Processing: Wire mesh, reactor baskets, acid-resistant fittings

-

6.Welding (ERNiCrMo-3): TIG/MIG filler wire for Inconel & stainless steel

-

7.High-Temp Heating: Electric heating coils, support wires

| Why Choose Us |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. Provide SGS TUV report.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

7.Provide one-stop service.

| Inconel 625 coil wire Packing |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa alloy’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,