Duplex Steel S31803 S32205 Bars

SASA ALLOY UNS S31803 is a duplex stainless steel grade which contains an equivalent 50:50 austenite, ferrite microstructure.The material used to make the UNS S31803 Round Bar combines good mechanical strength and ductility with moderate to good resistance to corrosion in a various environments.This Duplex Steel UNS S31803 Bars material is generally available in an annealed condition. In an annealed condition the yield strengths of the material is around 450 Mpa.In this video, we showcase the Positive Material Identification (PMI) testing conducted on Duplex Steel S31803 S32205 bars to verify their material composition and integrity. PMI testing is crucial for confirming alloy grades and preventing material mix-ups, ensuring the quality and reliability of our steel bars.

| Specifications of Duplex Steel S31803 Bars: |

Specifications : ASTM A276 / ASME SA276 / ASTM A479

Grade: S31803 S32205 F51

Length :5.8M,6M & Required Length

Round Bar Diameter : 4.00 mm to 200 mm

Bright Bar : 4mm – 150mm,

Surface Finish : Black, Bright, Polished, Rough Turned, NO.4 Finish, Matt Finish

Form : Round, Billet, Ingot, Forging Etc.

End : Plain End, Beveled End

| Duplex Steel S31803/S32205 Bars Equivalent Grades: |

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex S31803 / S32205 | 1.4462 | S31803 / S32205 |

| Duplex steel S31803 / S32205 Chemical Composition and Mechanical properties: |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 - 23.0 | 3.0 - 3.5 | 4.50 - 6.50 | 0.14 - 0.20 | 63.72 min |

| S32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 - 23.0 | 2.50 - 3.50 | 4.50 - 6.50 | 0.8 - 0.20 | 63.54 min |

| Element | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

| A479 Uns S31803 Bright Bar Condition: |

|

H&T

|

Hardened and tempered.

|

|

ANN

|

Annealed

|

|

PH

|

Precipitation hardened.

|

| Duplex Steel UNS S31803 Square Bar Surface finish: |

|

CD

|

Cold drawn

|

P

|

Polished

|

|

BD

|

Bright drawn

|

SRE

|

Slit rolled edge

|

|

CG

|

Centreless ground

|

HF

|

Hot finished

|

|

CF

|

Cold finished

|

HRAP

|

Hot rolled annealed and pickled

|

|

P&T

|

Peeled and turned

|

RT

|

Rough turned/peeled

|

|

ST

|

Smooth turned

|

PR

|

Peeled and reeled

|

| 2205 Black Bar Stock List: |

| Product | Diameter |

| duplex 2205 bar | Dia=66mm, Weight=27.1kg/m |

| Dia=90mm,Weight=50.5kg/m | |

| Dia=180mm,Weight=201.9kg/m |

| Why Choose Us : |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

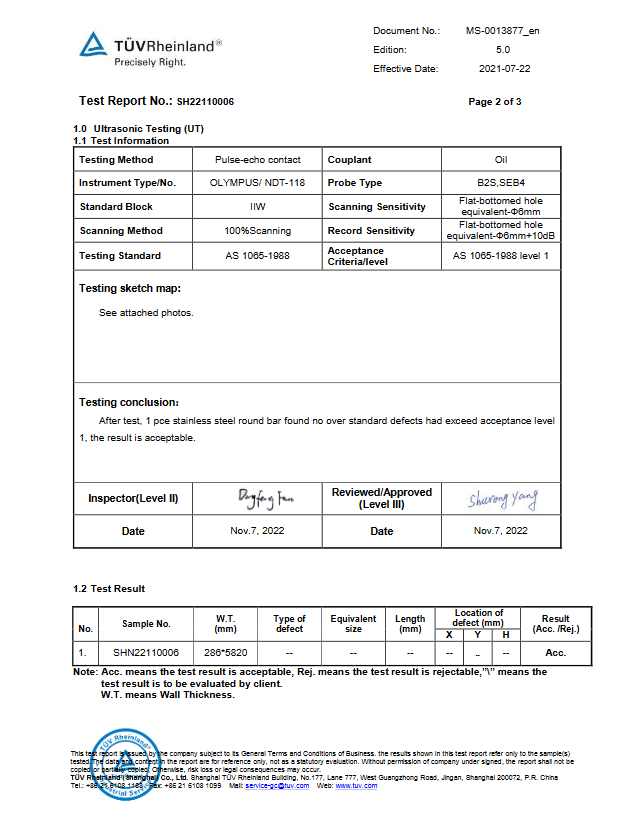

| SASA ALLOY'S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

UT Test Report:

|

|

| SASA ALLOY'S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. SASA ALLOY's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

1. Chemical Industry

2. Oil & Gas Industry

3. Petrochemical Industry

4. Power Genration Industry

5. Sugar Industry

6. Food Processing Industry

7. Paper & Pulp Industry

8. Offshore and Onshore Services

Terminal finished product: