Inconel 601 is a high-strength, corrosion-resistant nickel-based superalloy. It’s known for its excellent mechanical properties at both high and low temperatures, making it suitable for various demanding applications. The “601″ designation typically refers to its composition of approximately 50% nickel, 19% chromium, 18.5% iron, 5% niobium, and traces of other elements.

| Specifications of INCONEL 601 Strip: |

| Grade |

Inconel 601 | UNS N06601 |

| Standard |

ASTM B168

|

| Thickness |

0.15 mm to 3.50 mm

|

| Size |

1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Finish |

Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form |

Sheets, Plates, Coils, Slatting Coils, Perforated Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Hardness |

Annealed-pickled(soft), 1/4 hard, 1/2 hard, 3/4 hard & full hard (as rolled) etc. |

| Applications |

Off-Shore Oil Drilling Companies, Power Generation, Petrochemicals, Gas Processing, Specialty Chemicals, Pharmaceuticals, Pharmaceutical Equipment, Chemical Equipment, Sea Water Equipment, Heat Exchangers, Condensers, Pulp and Paper Industry |

| TYPE OF INCONEL 601 Strip: |

Inconel X750 2.4669 Nickel Strip |

Inconel 600 Nickel Alloy Strip |

601 Nickel Alloy Strip |

625 Nickel Alloy Strip |

N07750 Nickel Alloy Strip |

Inconel X750 N07750 Nickel Alloy Strip |

| EQUIVALENT GRADES OF INCONEL 601 Strip: |

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

| INCONEL 601 |

2.4851 |

N06601 |

NCF 601

|

NA 49

|

XH60BT

|

NC23FeA

|

NiCr23Fe

|

| CHEMICAL COMPOSITION OF INCONEL 601 Strip: |

| Grade |

C |

Mn |

Si |

S |

Cu |

Fe |

Ni |

Cr |

| INCONEL 601 |

0.10max |

1.00 max |

0.50 max |

0.015max |

1.0 max |

Bal

|

58.00 -63 |

21.00 – 25.00 |

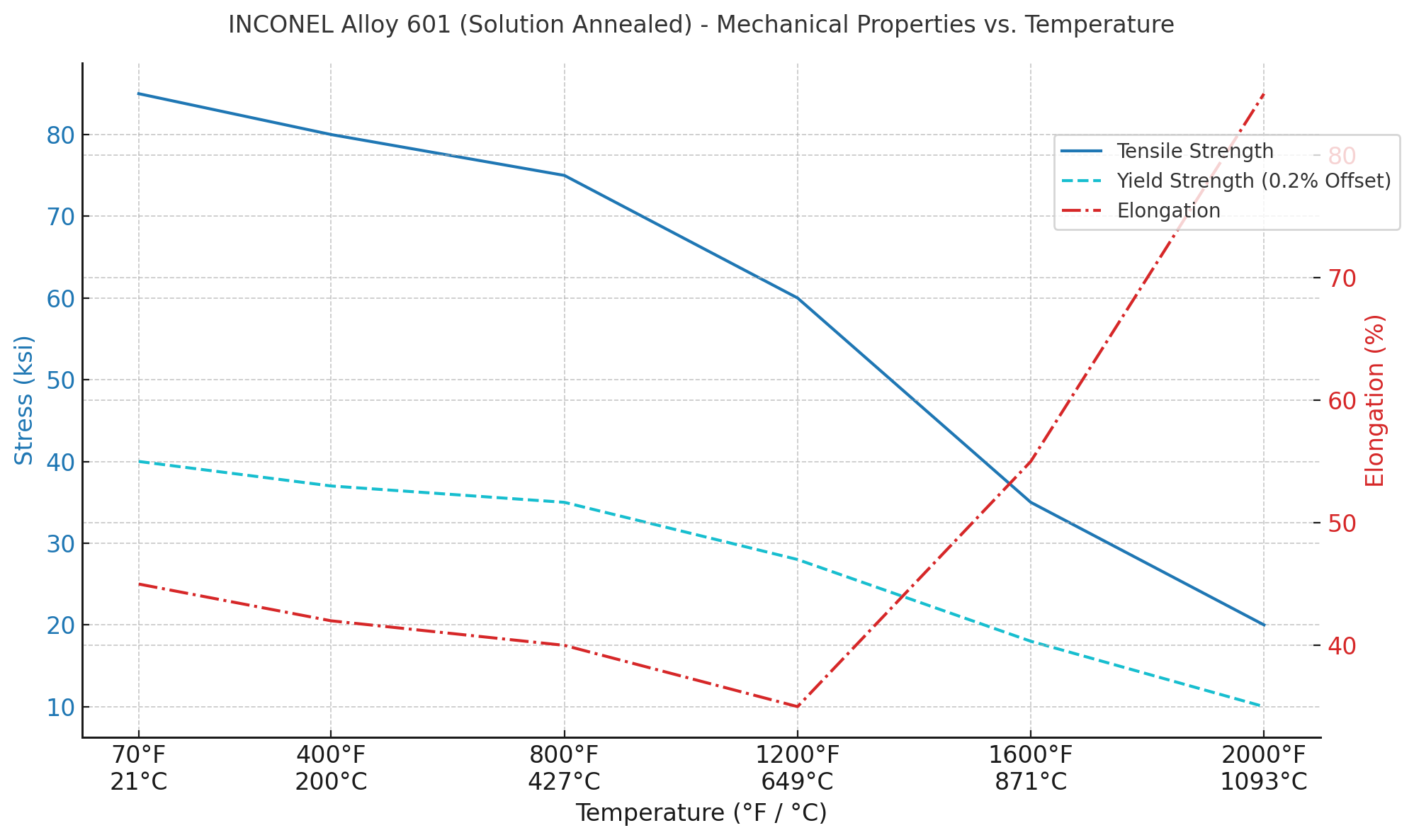

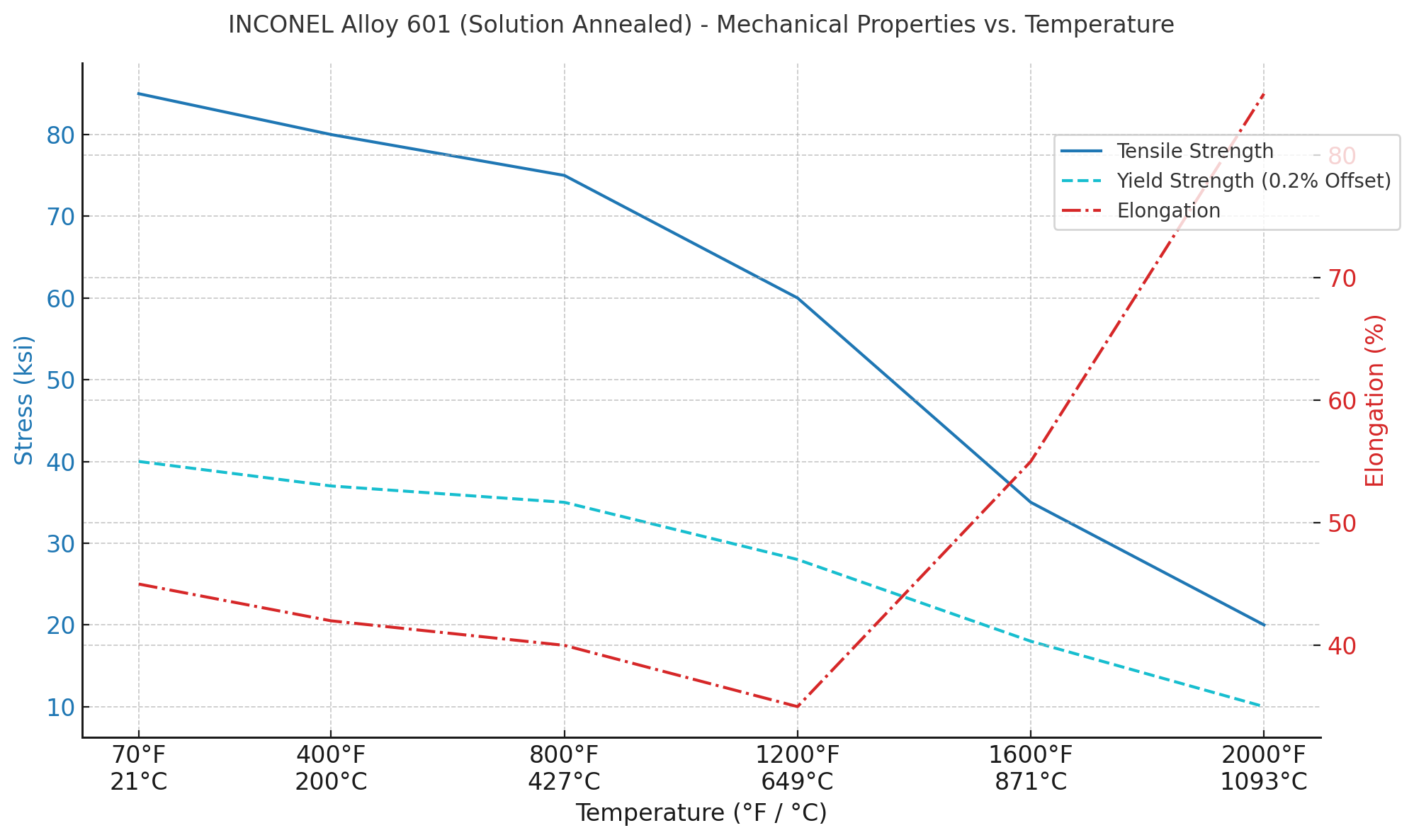

| Inconel Alloy 600 Strips Mechanical Properties: |

| Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| Inconel 600 |

8.47 g/cm3 |

1413 °C (2580 °F) |

Psi – 95,000 , MPa – 655 |

Psi – 45,000 , MPa – 310 |

40 % |

| Physical Constants and Thermal Properties: |

| Property |

Imperial Units |

Metric Units |

| Density |

0.293 lb/in³ |

8.11 g/cm³ |

| Melting Range |

2480 – 2571 °F |

1360 – 1411 °C |

| Specific Heat |

0.107 Btu/lb·°F |

448 J/kg·°C |

| Curie Temperature |

< -320 °F |

< -196 °C |

| Permeability at 200 Oersted (15.9 kA/m) |

1.003 |

– |

| Coefficient of Expansion (70–200°F / 20–100°C) |

7.60 × 10⁻⁶ in/in·°F |

13.75 µm/m·°C |

| Thermal Conductivity |

78 Btu·in/ft²·h·°F |

11.2 W/m·°C |

| Electrical Resistivity |

717 ohm·circ mil/ft |

1.19 µΩ·m |

| Typical Mechanical Properties (Solution Annealed) |

| Rupture Strength (1000 h) |

Temperature (°F) |

Temperature (°C) |

ksi |

MPa |

| |

1200 °F |

650 °C |

28.0 |

195 |

| |

1400 °F |

750 °C |

9.1 |

63 |

| |

1600 °F |

870 °C |

4.3 |

30 |

| |

1800 °F |

980 °C |

2.1 |

14 |

| |

2000 °F |

1095 °C |

1.0 |

7 |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa alloy’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Previous: ASTM B168 Inconel 600 Strips

Next: ASTM B443 2.4856 N06625 Inconel 625 Strips