Inconel 601 round bar suppliers, Inconel 601 Flat Bar, Inconel 601 Hex Bar Suppliers in China, Inconel 601 Rod, Alloy 601 Hollow Bar Stockist in China, Inconel Alloy 601 Round Rod distributor, Inconel 601 round bar manufacturer in China.

The properties of Inconel 601 Round Bar make it a material of broad utility in such fields as thermal processing, chemical processing, pollution control, aerospace, and power generation. Inconel 601 Hexagonal Bar, Inconel 601 Hollow Bar and Inconel 601 Forged Bar exhibits good weldability and is readily joined by conventional welding products and processes. Inconel 601 Hex Bar, Inconel 601 Hex Rod and Alloy 601 Round Bar’s properties make it a material of broad utility in fields like thermal processing, chemical processing, pollution control, aerospace, and power generation.

| Inconel 601 round bar Specification |

| Grade |

Inconel 601 – UNS N06601 |

| Specification |

ASTM B166 UNS N06601 |

| Inconel 601 Round bar size |

Diameter: 3mm~800mm |

| Inconel 601 Angle bar size |

3mm*20mm*20mm~12mm*100mm*100mm |

| Inconel 601 Square bar size |

4mm*4mm~100mm*100mm |

| Inconel 601 Flat bar size |

Thickness: 2mm~100mm |

| Width: 10mm~500mm |

| Inconel 601 Hex Bar size |

2mm~100mm |

| Inconel 601 Billet Size |

1/2″ to 495mm Diameter |

| Inconel 601 Rectangles Size |

33mm x 30mm to 295mm x 1066mm |

| Inconel 601 Round Bar Standard Dimensions |

As the customer request |

| Finish |

Bright, Polish, Bright, Rough Turned, Grinding, Centreless Ground & Black |

| Tolerance |

H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface |

Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition |

Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Annealed round bar |

| Technique |

Inconel 601 Hot Rolled, Cold Rolled, Cold Drawn, Forged Round Bar, Rod |

| Inconel 601 Bar Type |

Drawn Bar, Rolled Bar, Forged Bar, GFM Forged Bar, Open Die Bar, Forged Stepped Shafts, Forged Flat Bar, Forged Square Bar |

| Also Check price list of |

Inconel Round Bar, Inconel 625 Round Bar, Inconel 718 Round Bar, Hastelloy Round Bar, Monel Round Bar, Titanium Round Bar, Copper Nickel Bar, Stainless Steel Round Bar |

| Form |

Round, Rod, Precision Ground Bar, Square, Round Rod, Hollow, Hex (A/F), Triangle, Rectangle, Threaded, T-Bar, Half Round Bar, Flat Bar, Rings, Blocks, Billet, Ingot, I/H Bar, Angle, Channel Bar, Profiles, Forging Etc. |

| Our Inconel 601 round bar conforms to NACE MR0175/ISO 15156 |

Inconel 601 bar properties

ASTM B 166/ASME SB 166

DIN 17752

DIN 17753

DIN 17754

EN10095

ISO 9723

ISO 9724

ISO 9725

| STANDARD |

WERKSTOFF NR. |

UNS |

GOST |

AFNOR |

JIS |

BS |

EN |

OR |

| Inconel 601 |

2.4851 |

N06601 |

XH60BT |

NC23FeA |

NCF 601 |

NA 49 |

NiCr23Fe |

ЭИ868 |

| Inconel Alloy 601 Round, Bright, Hex, Threaded Bar Chemical Composition: |

| Grade |

Ni |

Cr |

Fe |

C |

Mn |

S |

Si |

Cu |

| Inconel 601 |

58.0 – 63.0 |

21.0 -25.0 |

Balance |

0.10 max |

1.0 max |

0.015 max |

0.5 max |

1.0 max |

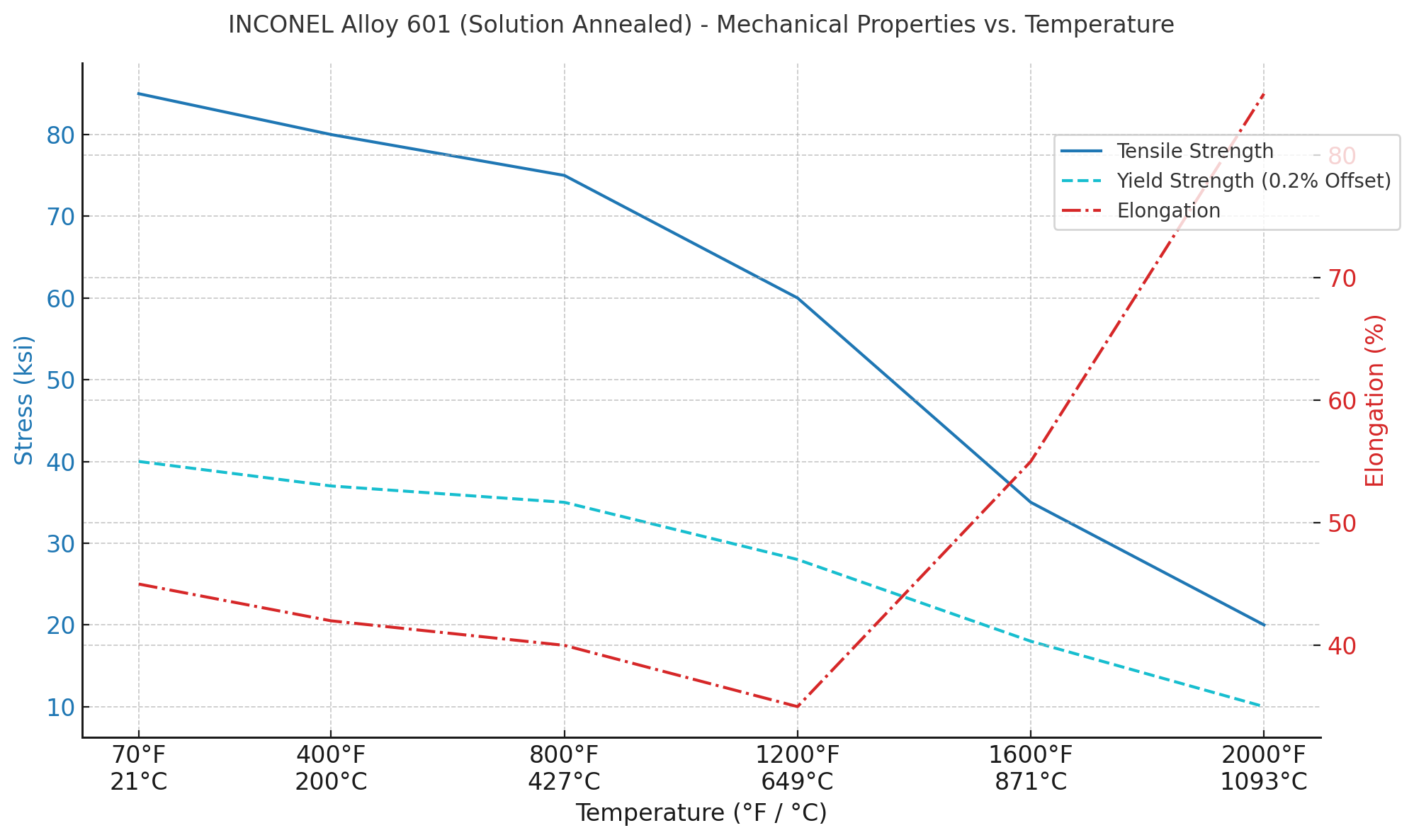

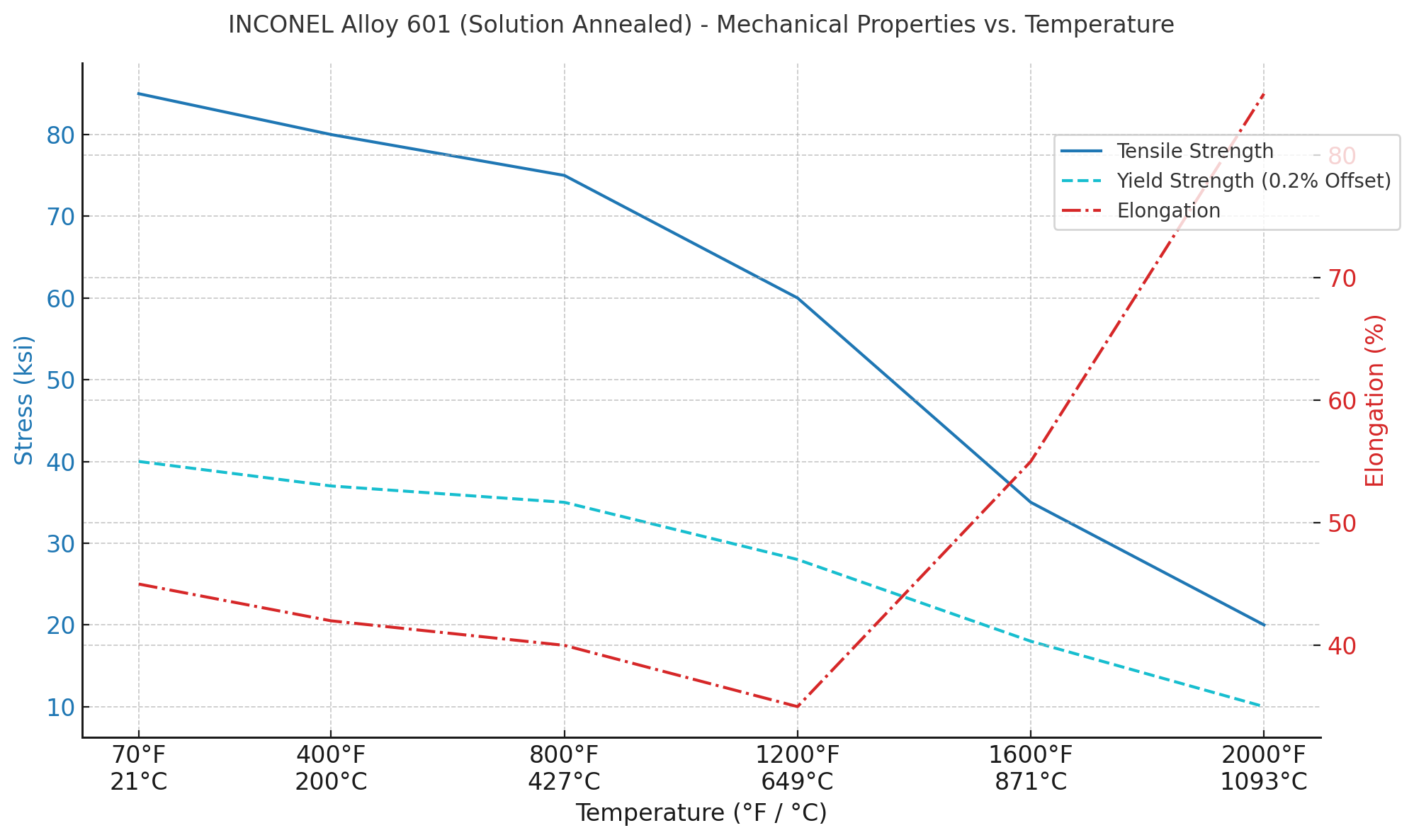

| Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| 8.1 g/cm3 |

1411 °C (2571 °F) |

Psi – 80,000 , MPa – 550 |

Psi – 30,000 , MPa – 205 |

30 % |

| Physical Constants and Thermal Properties: |

| Property |

Imperial Units |

Metric Units |

| Density |

0.293 lb/in³ |

8.11 g/cm³ |

| Melting Range |

2480 – 2571 °F |

1360 – 1411 °C |

| Specific Heat |

0.107 Btu/lb·°F |

448 J/kg·°C |

| Curie Temperature |

< -320 °F |

< -196 °C |

| Permeability at 200 Oersted (15.9 kA/m) |

1.003 |

– |

| Coefficient of Expansion (70–200°F / 20–100°C) |

7.60 × 10⁻⁶ in/in·°F |

13.75 µm/m·°C |

| Thermal Conductivity |

78 Btu·in/ft²·h·°F |

11.2 W/m·°C |

| Electrical Resistivity |

717 ohm·circ mil/ft |

1.19 µΩ·m |

| Typical Mechanical Properties (Solution Annealed) |

| Rupture Strength (1000 h) |

Temperature (°F) |

Temperature (°C) |

ksi |

MPa |

| |

1200 °F |

650 °C |

28.0 |

195 |

| |

1400 °F |

750 °C |

9.1 |

63 |

| |

1600 °F |

870 °C |

4.3 |

30 |

| |

1800 °F |

980 °C |

2.1 |

14 |

| |

2000 °F |

1095 °C |

1.0 |

7 |

Inconel DIN 2.4851 Forged Round Bars, Inconel 601 Rod, Inconel 601 Cold Drawn Bar Leading Manufacturers, Inconel UNS N06601 Round Bars exporter in China, Alloy 601 Hollow Bar Exporters.

Previous: Inconel 600 Bar

Next: Inconel 625 Bar